Between 2016 and 2017 in Castelbelforte, in a fertile area of the Po Valley between Mantua and Verona, Idromeccanica Lucchini completed a high-tech intervention for the cultivation of tomatoes.

The area, especially famous for rice cultivation, is characterized by the presence of large single-lot farms, which combine the plantation of rice also livestock. Idromeccanica Lucchini intervention at the farm Terreni Parolara, therefore, is an element of novelty for the territory and a significant case history from which to take inspiration for other work.

The initial context

The Farm Terreni Parolara, is already famous for innovation and technological research. In recent years, in fact, major investments have been made to generate renewable energy through photo-voltaic and biomass plants. The intervention of Idromeccanica Lucchini was designed, built and optimized around this extraordinary internal energy production.

What the customer needed

The company needed the construction of a greenhouse plant for the development and growth of soil-less tomato seedlings. The type of cultivated tomato is a classic ribbed Rugantino intended primarily for GDO and canteens and perfect for salads. It is a slow ripening product still sold with the double color to reach the perfect ripeness at tasting time. This type of tomato has been selected for its being relative easy to be cultivated in the start-up phase. As this territory was almost basically dedicated to rice cultivation, it was necessary to start with a low problematic product, which could immediately guarantee an adequate yield. As Matteo Lucchini, Project Manager of the entire operation, has always said, in order to maximize the production and the quality of the product it is also essential to take care of the health of the plant and then grow the tomato plants in a protected environment, with ideal light and nourishment conditions and away from harmful external agents.

Lucchini Intervention

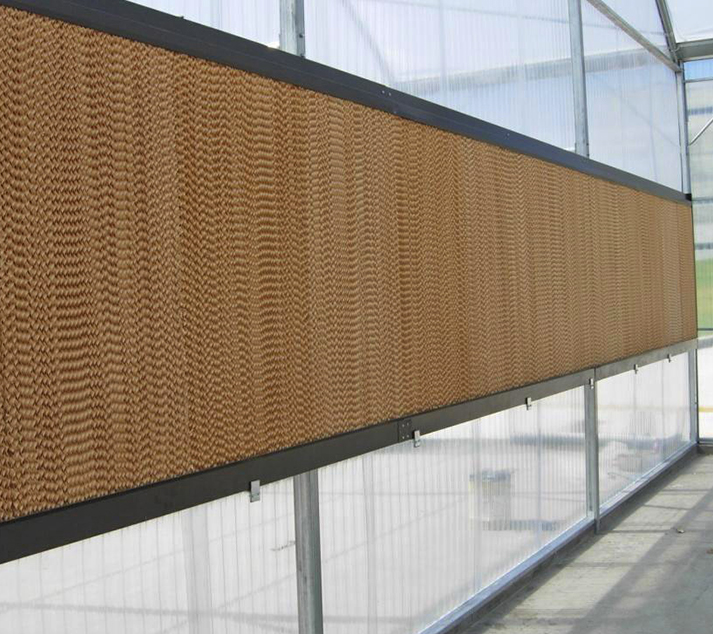

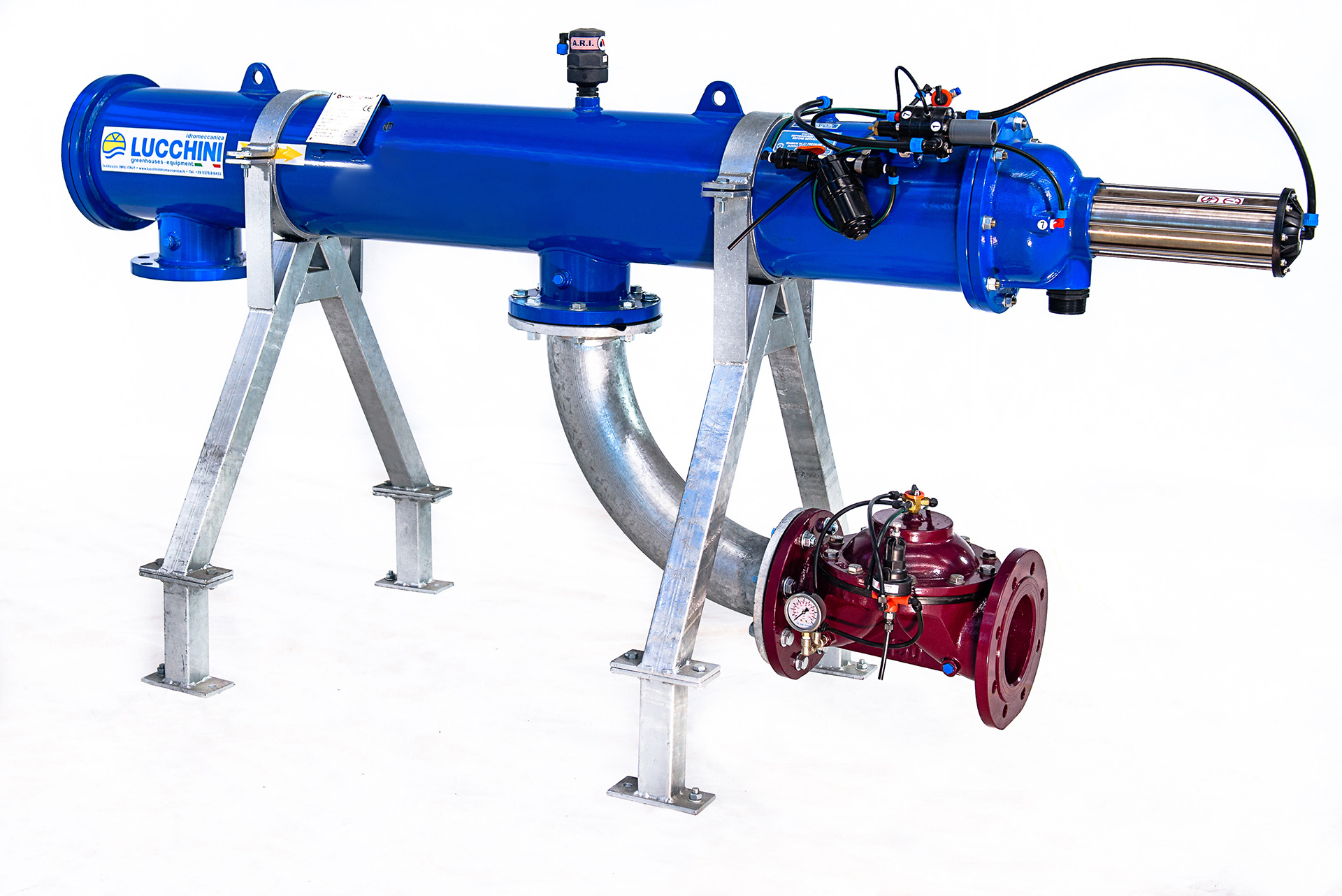

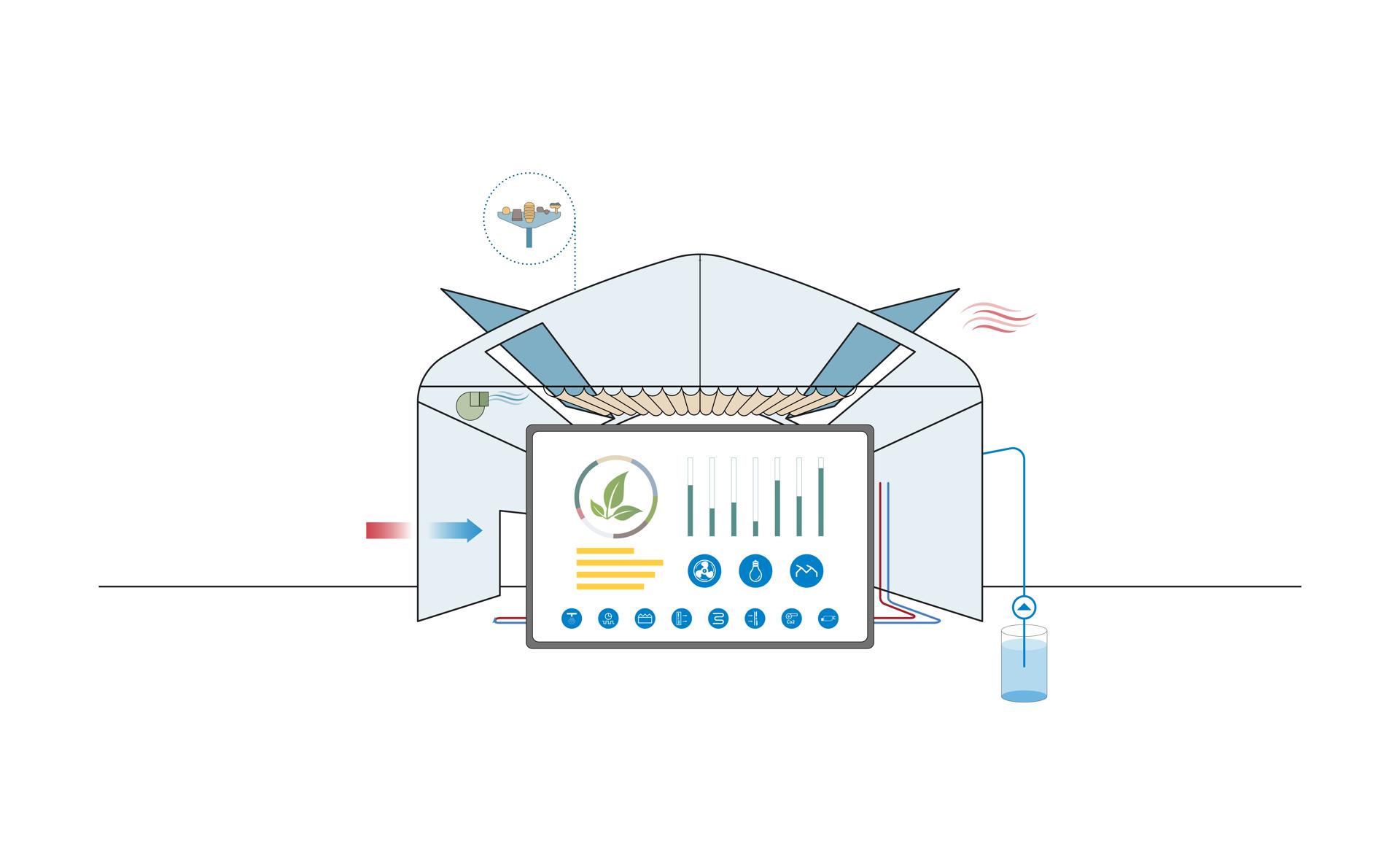

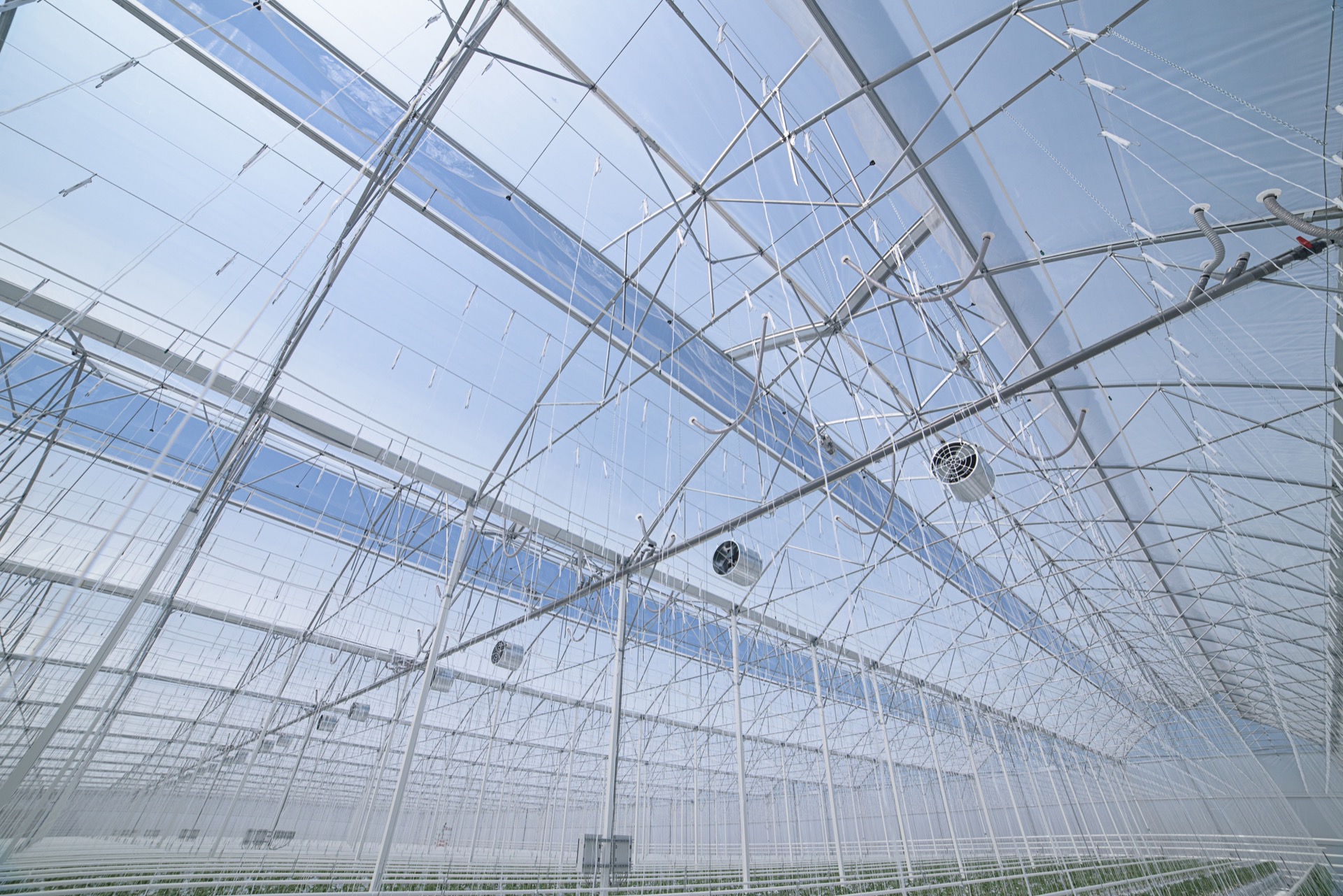

Once the premises have been analyzed, Idromeccanica Lucchini agronomists and designers, who have been specializing in tomato processing for years, have developed a complex intervention based on the Multiatlantic greenhouse. In order to maximize both the quality and quantity of production and to ensure the well-being of tomato plants, they are grown and cared for in a controlled environment inside the greenhouse and, once ready, transplanted in open field for the production of the fruit. Inside the greenhouse, the plants are soil-less grown and, in this delicate phase of their growth, receive the right amount of light and heat. All plant components are perfectly automated:

• Closed circuit inert substrate with minimum water impact

• Heating and plant nourishment also remotely managed to give the greenhouse all the characteristics of an avantgarde intervention 4.0.

The right heat for tomato plants

In order to better regulate the temperature of the greenhouse, Idromeccanica Lucchini has designed a tomato soil-less crop system with thermal layer and used the energy derived from biogas plants for winter heating. This allows to obtain a long summer cycle, from transplant to harvest, which lasts from January to November. When the biogas plant is not sufficient to support all the energy needs of the greenhouse, there is a backup heating system obtained through traditional fuels with low environmental impact.

The correct light amount

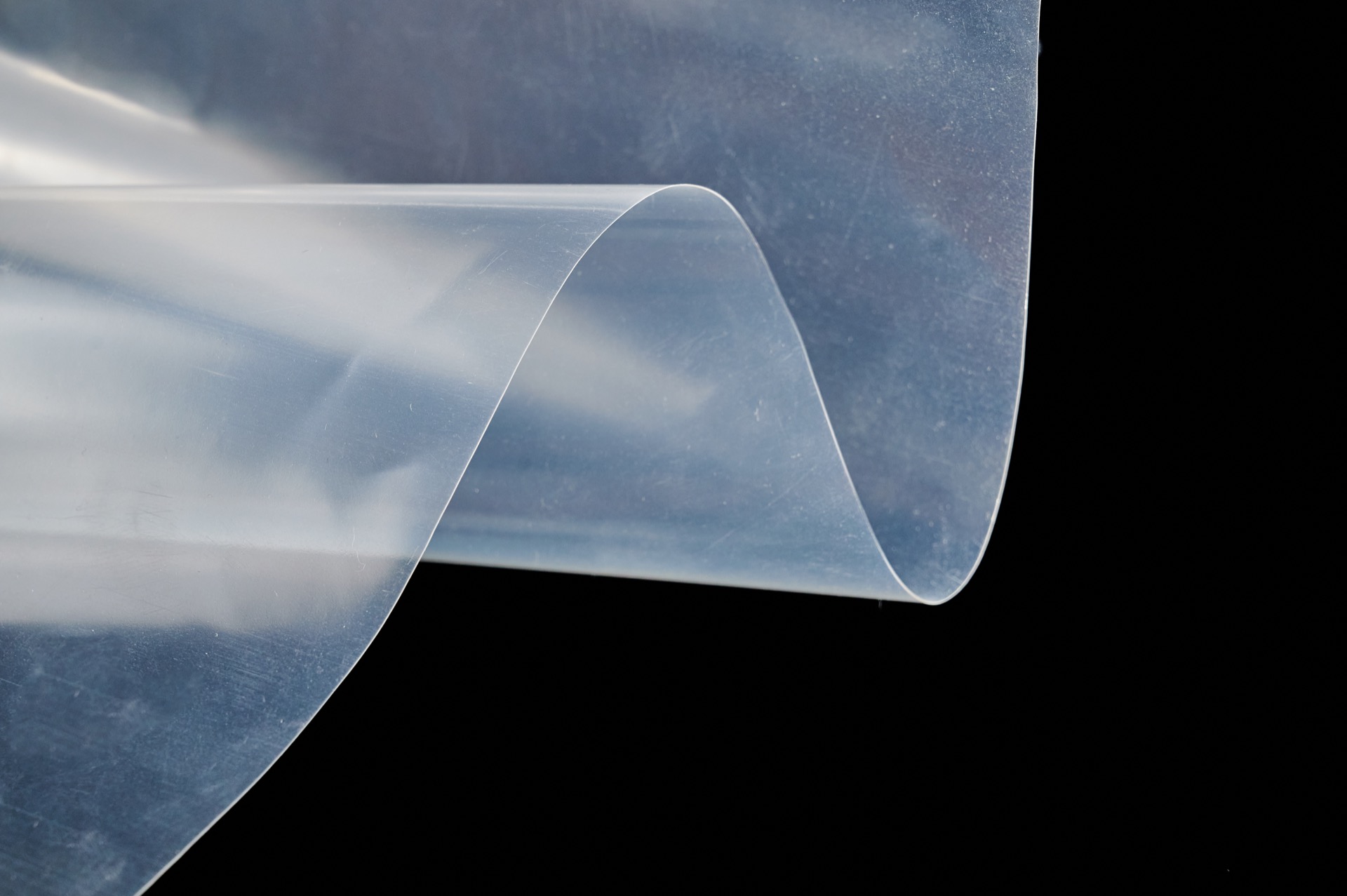

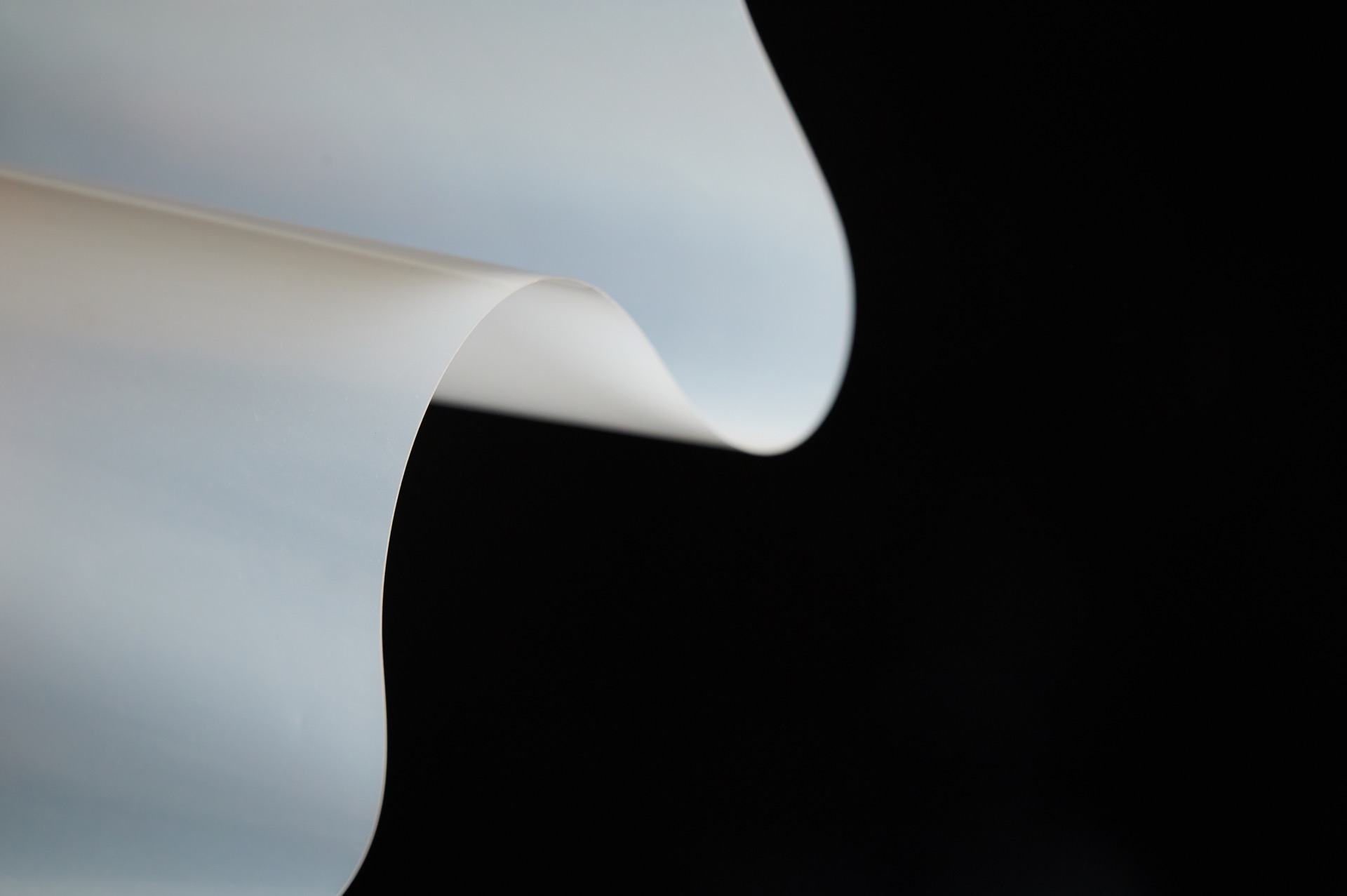

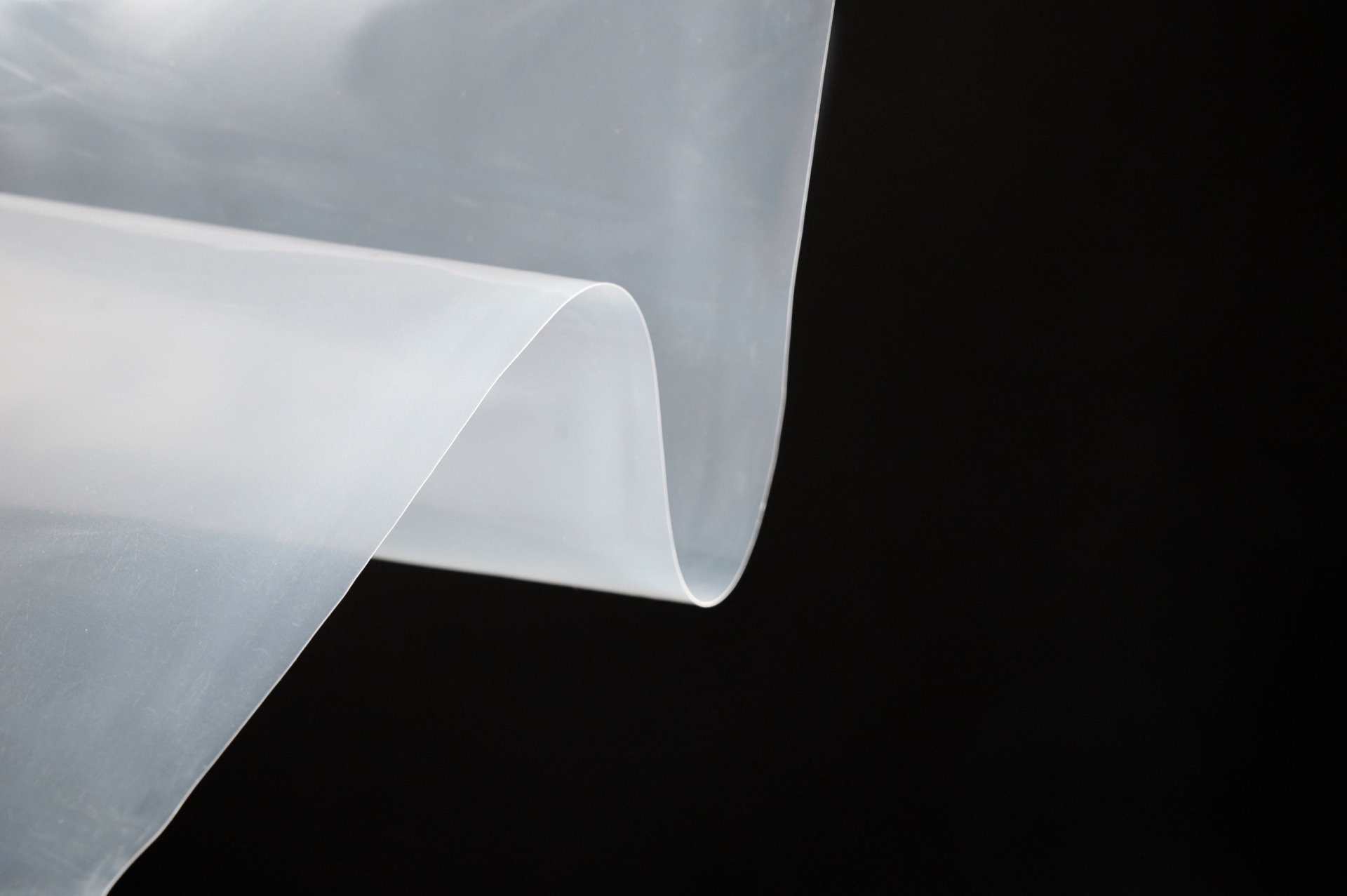

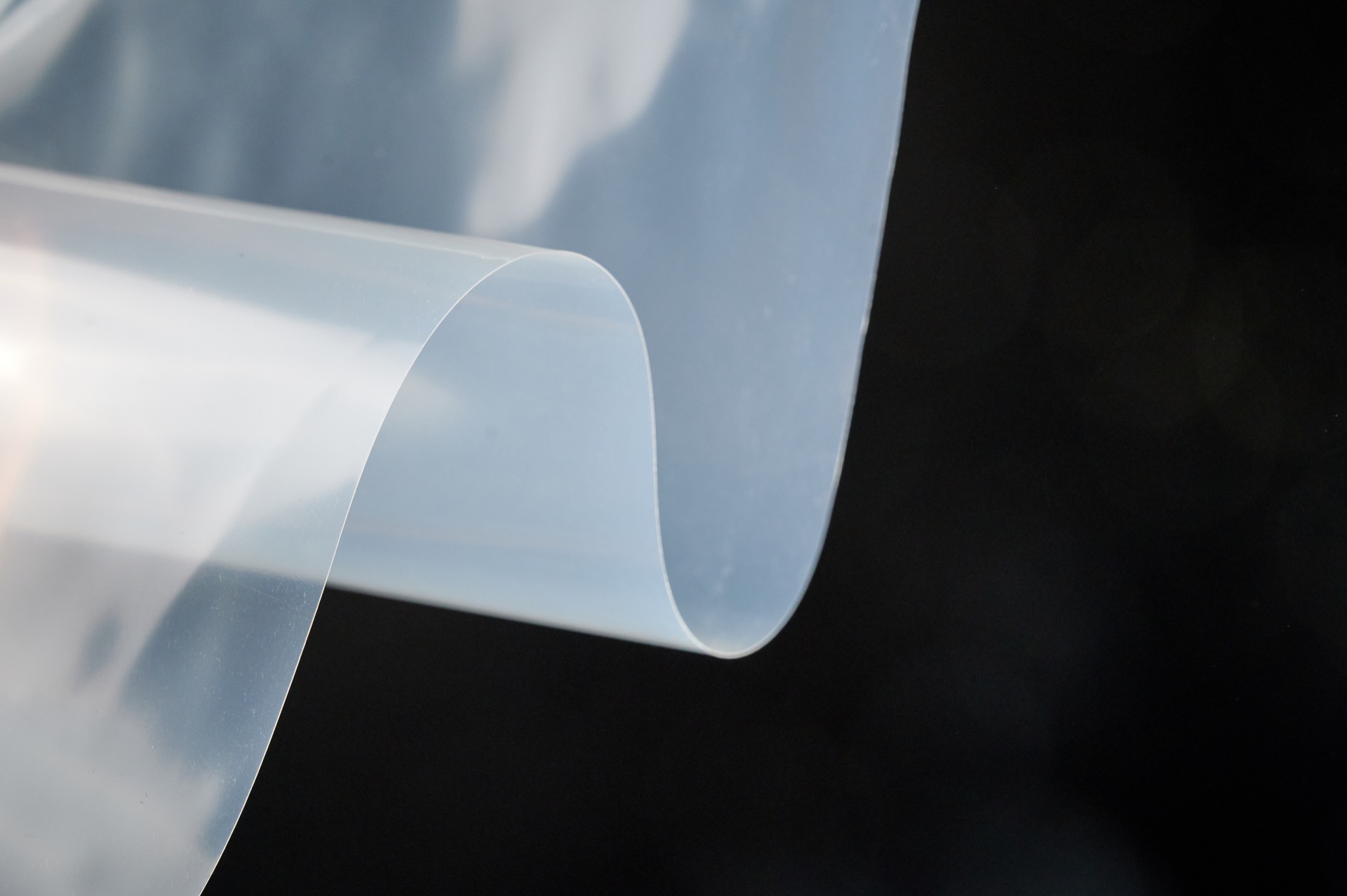

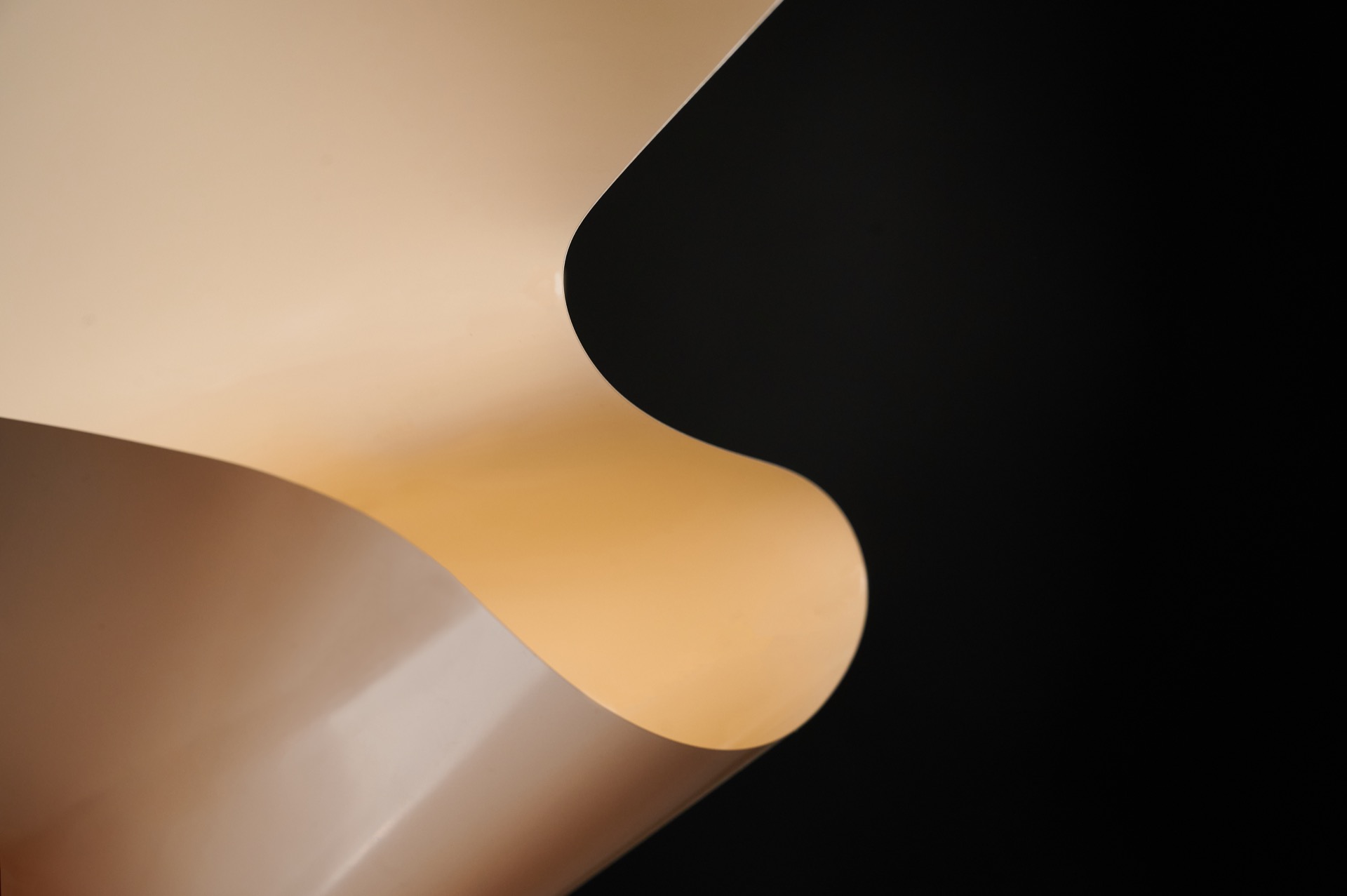

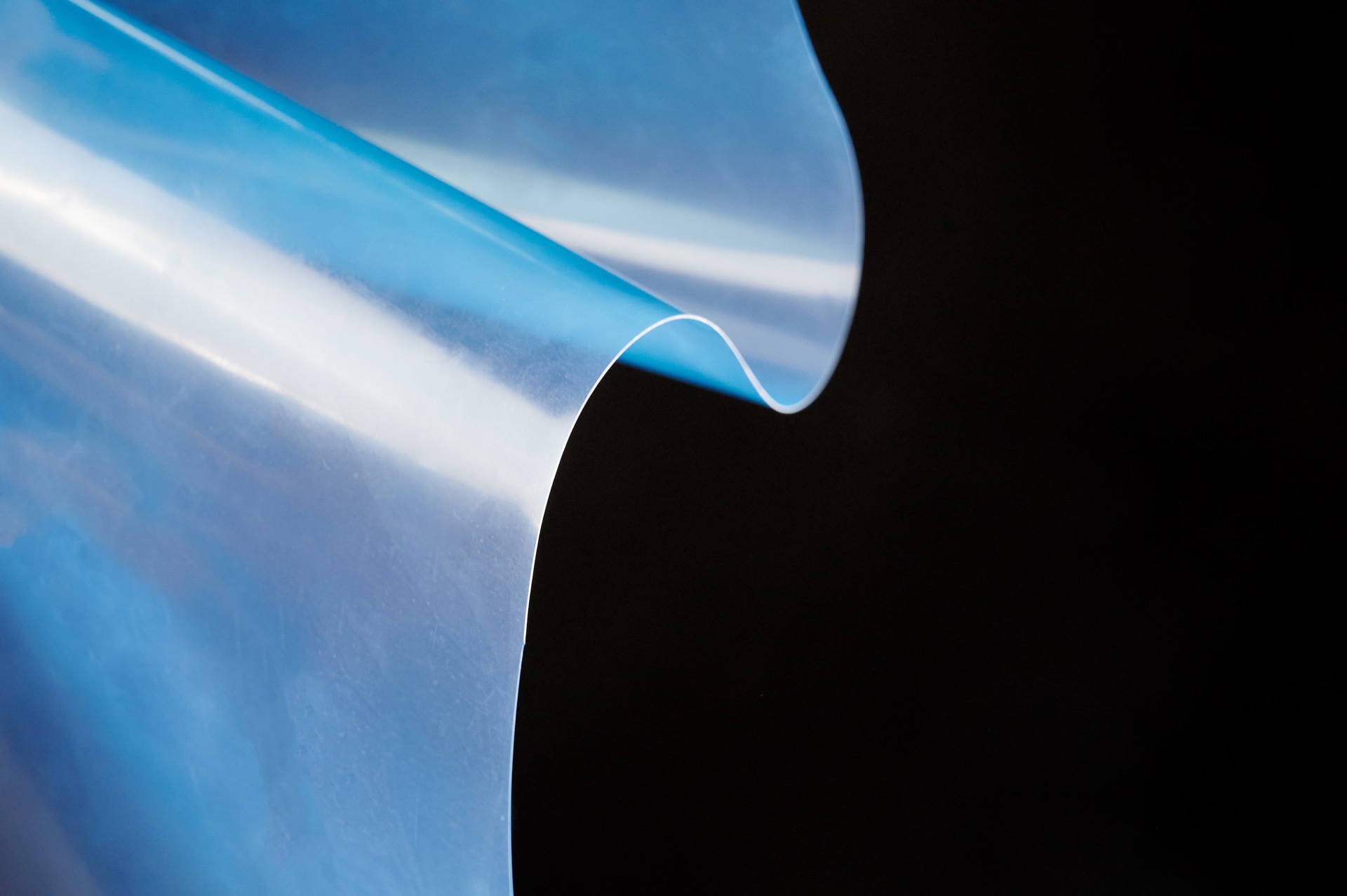

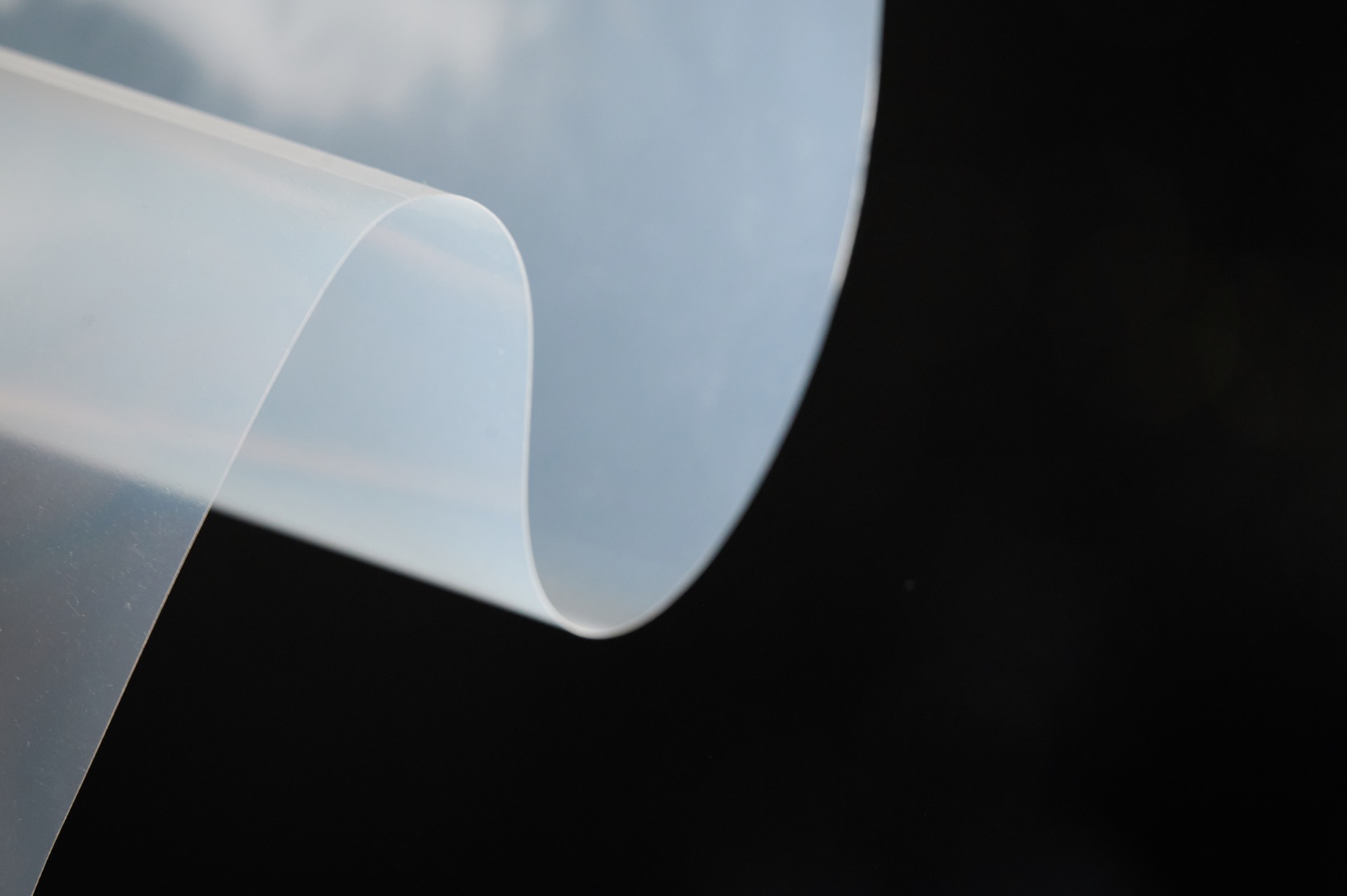

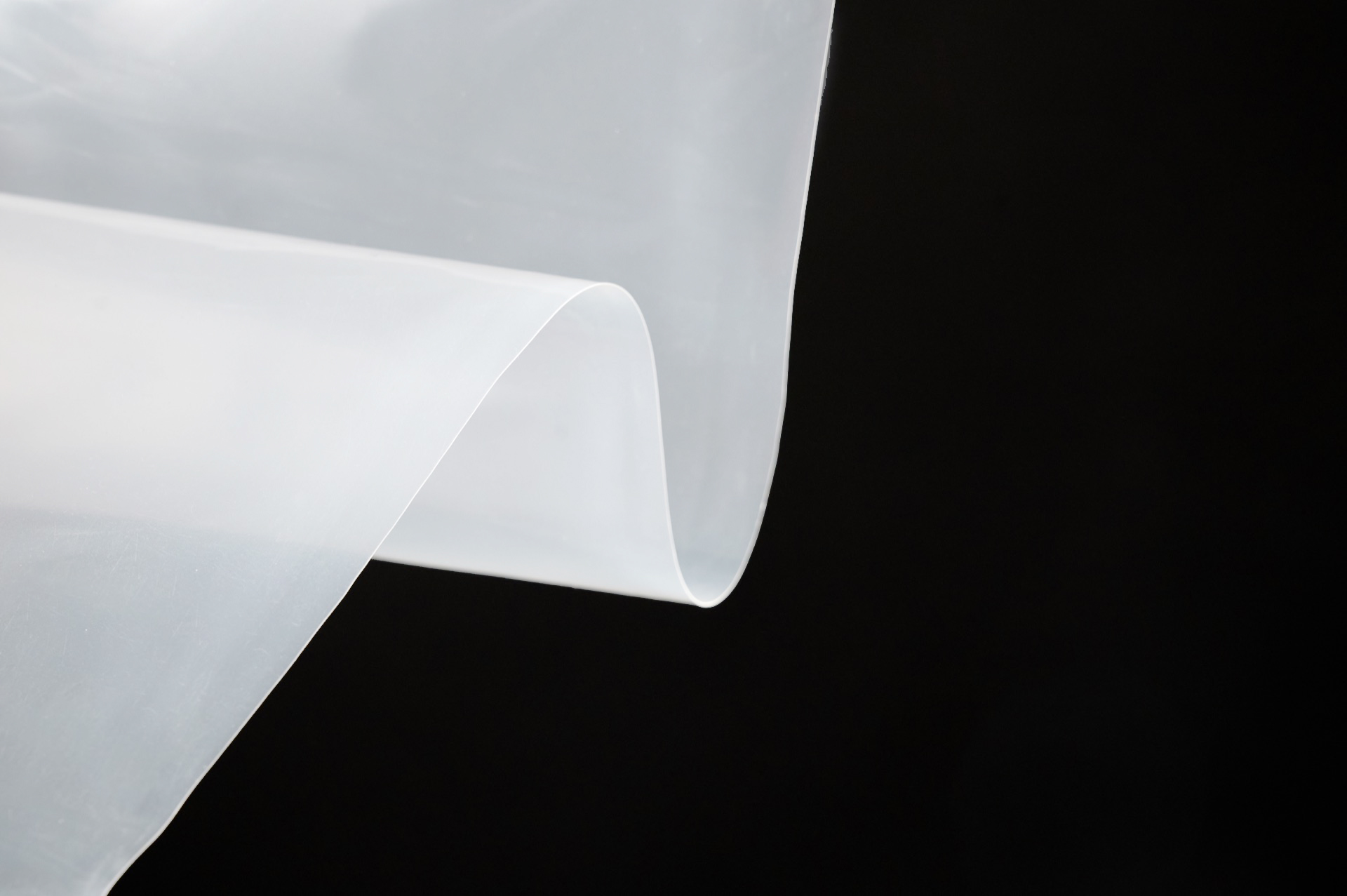

The strategies to have the right amount of light in all periods of the year were two: first, the load-bearing structures of the greenhouse were hot-galvanized white and finally was a diffused light plastic film. During winter season the white of the galvanizing reflects the light that is optimized and diffused by the cloth, while during the summer the white of the structures attracts less thermal energy and the cloth plays a protective function. Thanks to these combined actions, the plants immediately proved to be more vigorous and healthy and, once transplanted, they obtained a better productivity for quality and greater quantity.

From design to training

The intervention of Idromeccanica Lucchini was made possible by an enlightened client who believed and invested in a long-term project. The work of Idromeccanica Lucchini did not end, in fact, with the delivery of the greenhouse, but continued during the training of the greenhouse managers and staff. For a proper management of the greenhouse, in fact, the staff was carefully selected and trained through a mix of theoretical lessons (including plant biology, chemistry and computer science) as well as being followed by an agronomist Lucchini for training "on-field". It is Matteo Lucchini himself conveying the satisfaction, personal as well, for the success of the project: "For Idromeccanica Lucchini was very satisfactory to see the staff willing to learn and to be able to master such a complex technology. It was a wonderful teamwork, which brought together the staff of Idromeccanica Lucchini and that of Terreni Parolara Farm for the duration of the start-up phase and beyond." The success of the initiative has been such as to fastly obtain great awards in terms of sales also in the GDO Sector.

The obtained results

The whole plant of greenhouses has guaranteed an excellent yield per square meter and a final product fully purchased by buyers and without dispute. The tomatoes were nice to look at and taste. The entire production cycle was perfectly carried out and according to agronomic parameters. Customer satisfaction with the greenhouses of Idromeccanica Lucchini will most likely lead to a forthcoming expansion of the plant.