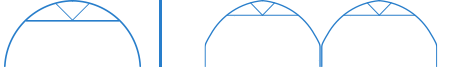

Industry 4.0 is a plan to bring production processes towards the fourth industrial revolution. In particular, Industry 4.0 aims at an interconnected production that allows the collection, reading and analysis of data to obtain improved production processes through previous experiences.

Grenhouses automationing in 4.0

Idromeccanica Lucchini goal is to bring agriculture in the World 4.0, making automated procedures that until now in greenhouses have been manual and without any systemic control.

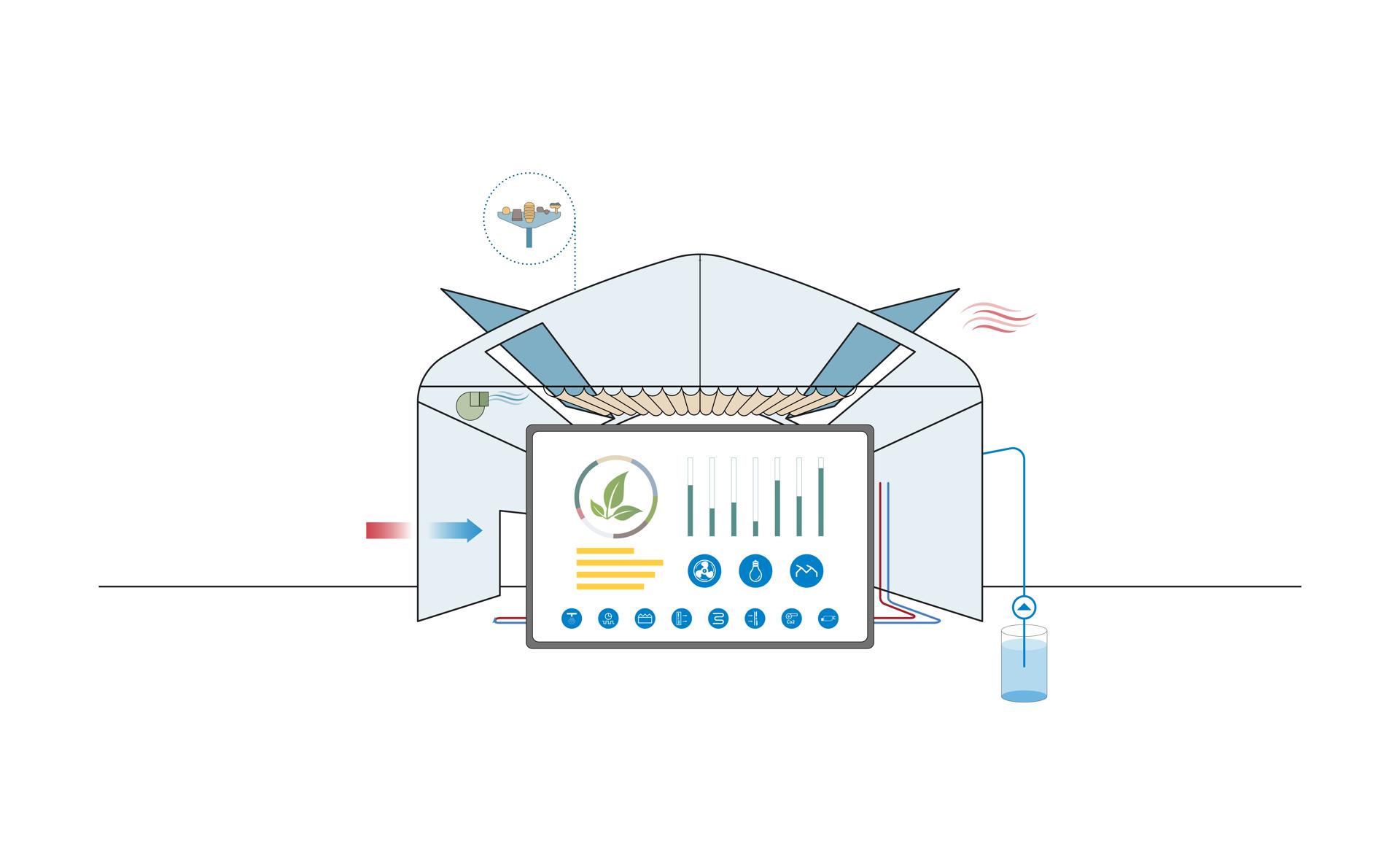

Automated greenhouses are better greenhouses as they are constantly monitored. The monitoring allows to have data analysis and continuous reporting that puts the production directly in contact with the planning. Data monitoring process is not an innovation in itself, but to date it has been carried out through data collected with pen and paper without a real scientific method. In order to project agriculture towards the future, instead, we need a development that, through automation, allows a systematic collection of data.

The meaning of Data collecting

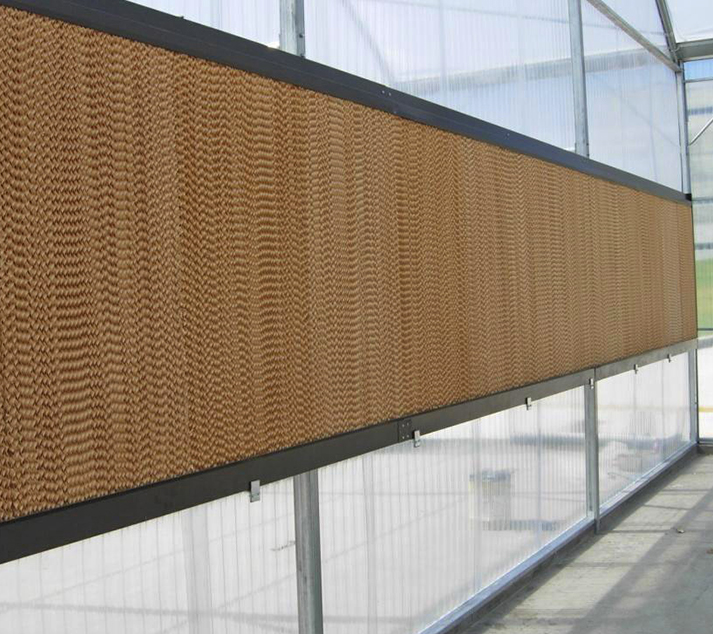

Collecting and analyzing data is critical in agriculture as and more than in industry. Through the monitoring and study of the various stages of production, it is possible to learn how much water is needed and how much is wasted in the various production cycles, what is the best temperature, what are the costs of air conditioning, what are the best times for fertirrigation and so on. Better knowledge of production processes allows you to better plan deadlines, deliveries, flows and yields, also considering the climatic variables and various other parameters.

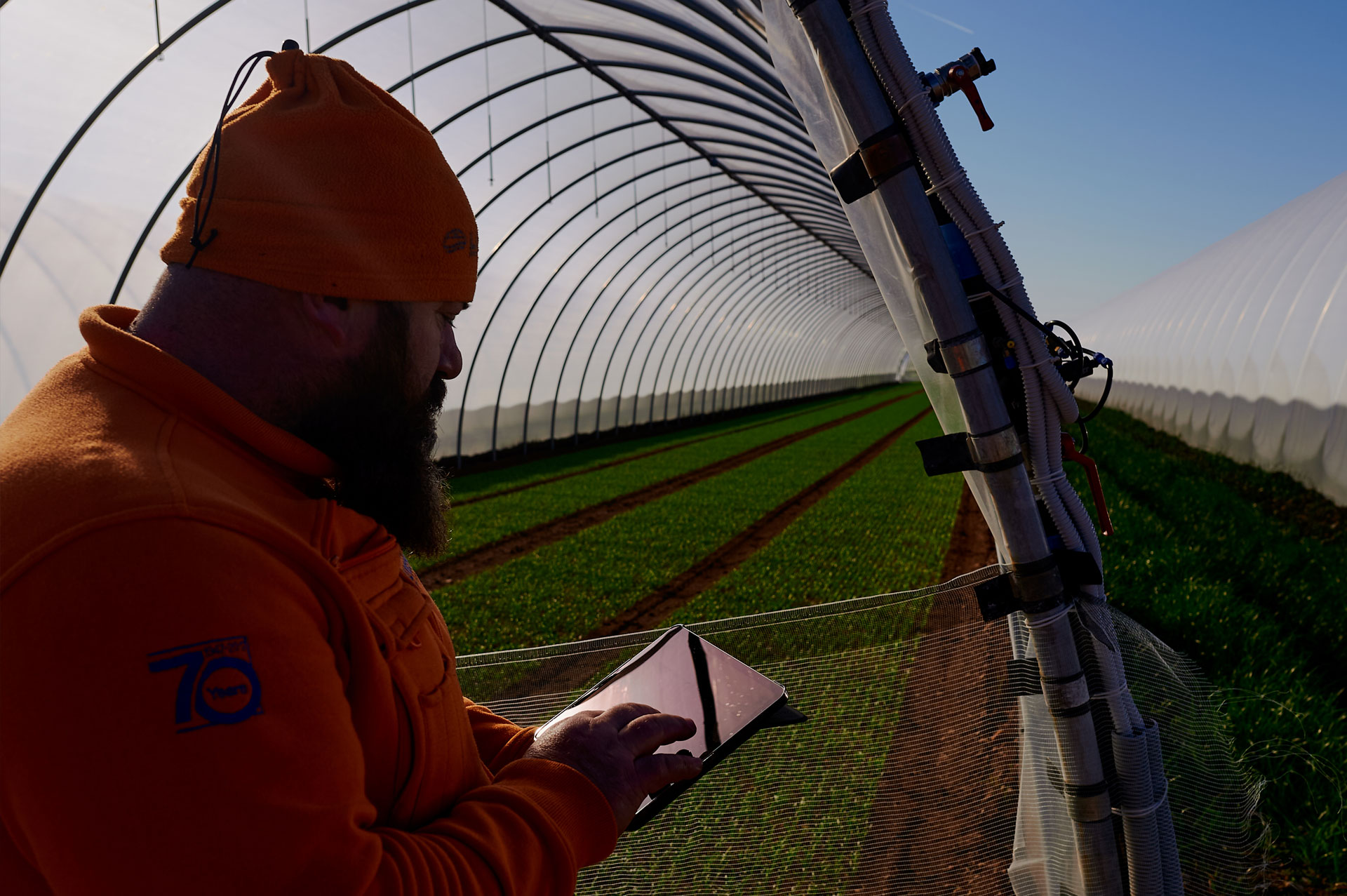

Idromeccanica Lucchini in 4.0

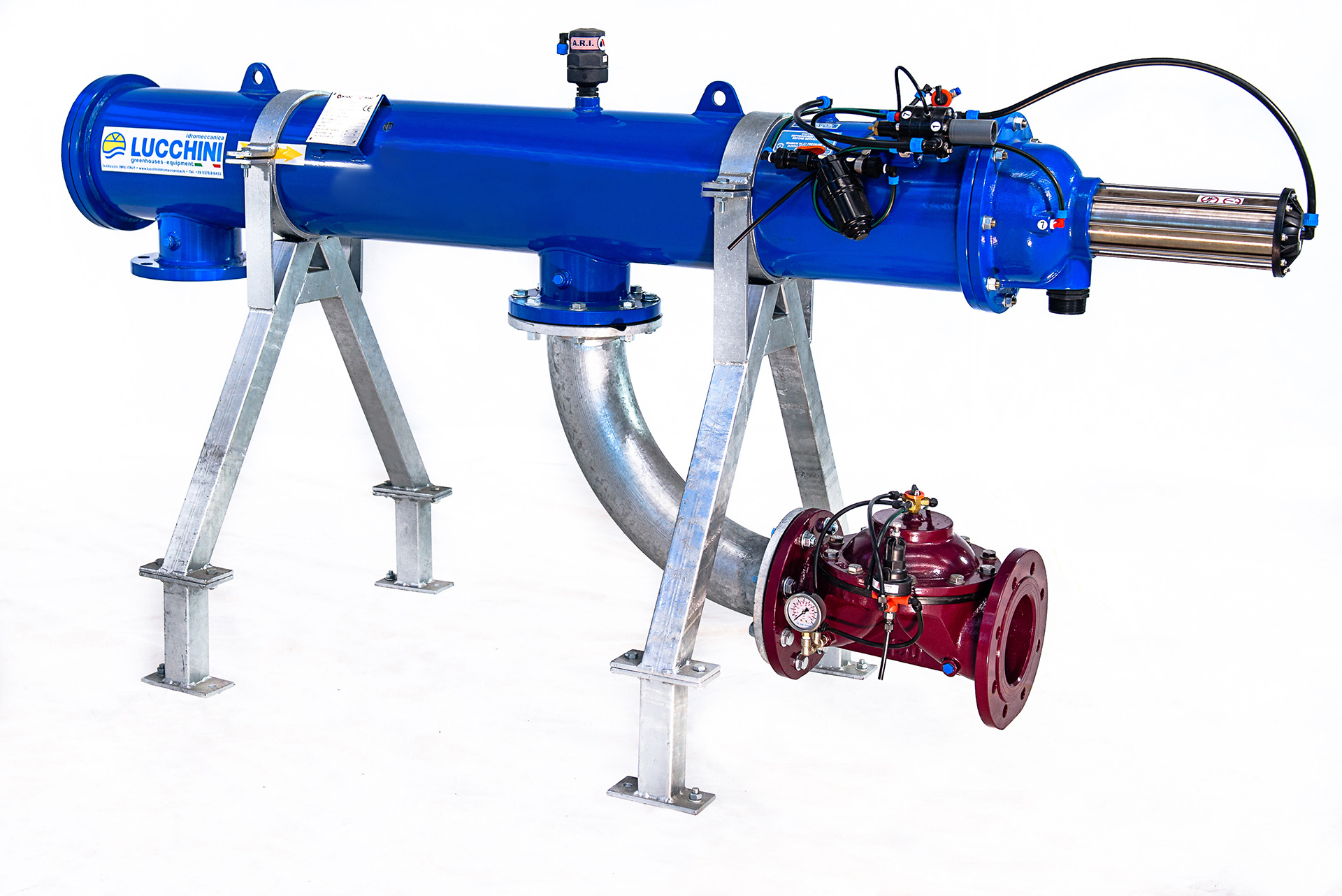

Idromeccanica Lucchini has immediately adhered to the Industry 4.0 plan and over the years has collected and analyzed data from existing systems and innovative systems to create its own hardware and software platform that historicizes data (temperature, humidity, water, light, etc.). With the data analysis it is possible to create a report and an active database that indicates how much energy, how much humidity etc. are useful to obtain a certain production, facilitating and automating the process itself. The platform of Idromeccanica Lucchini also allows to know costs and revenues based on energy, fuels and products used to obtain a certain yield, making safe and automatic processes that until now were uncertain and manual. The new technology of Idromeccanica Lucchini is a completely web platform, which interfaces with all systems even already existing, acquires data and creates reports related to production. Cross-reference the data to establish ways and times of production to achieve higher yields at optimized costs. "If I measure it I can improve it".

Idromeccanica Lucchini is better

Many greenhouse manufacturers have developed and proposed automatisms to meet the needs of farms in the field of Industry 4.0, but often it is simply a matter of data collection units that, however, by itself, they do not guarantee the certainty of obtaining public funding. Idromeccanica Lucchini, always faithful to the mission of placing itself not only as a supplier, but as a real partner that accompanies customers before and after the purchase, supports companies taking charge of bureaucratic burdens and making available not only the product, but also the advice of good professionals. Agronomists deal with the optimization of production, while technical system integrators coordinate electricians and plumbers for the development of the hardware and software on the specific needs of the customer, integrating the new technologies installed, with existing installations. At the end of the process the machines are certified for 4.0 certification. The customer therefore finds a modern and standardized greenhouse for Industry 4.0 without any stress of practice management, but with a project built to his specific needs.