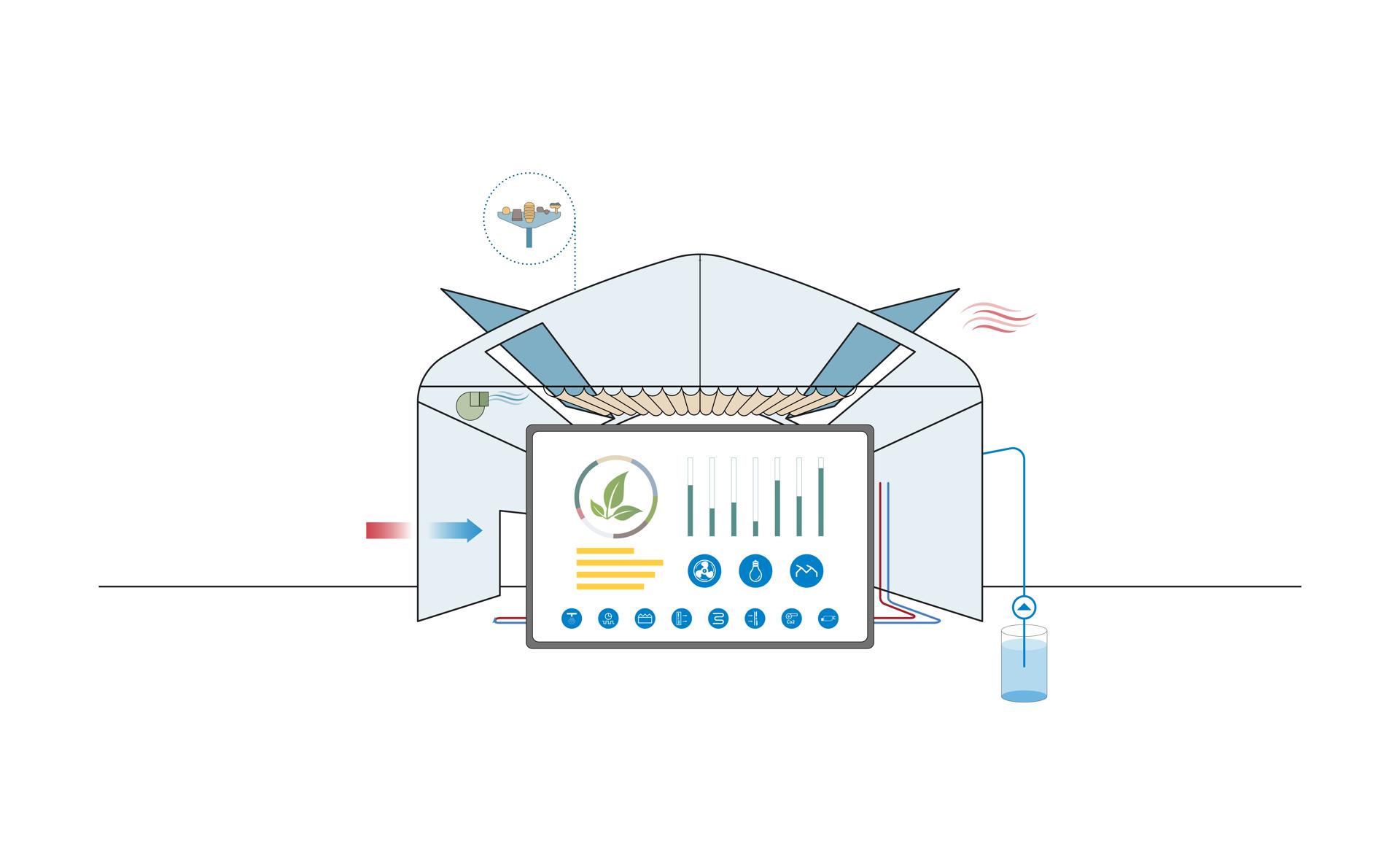

In the world of agricultural production, logistical efficiency plays a key role. And while the focus is on product quality, the management of internal flows, from the movement of materials to storage space, is equally crucial to ensure maximum output and continuous optimisation of resources. Lucchini, at this juncture, has demonstrated its ability to meet this challenge by offering tailor-made logistics solutions that combine high technology, advanced engineering and a truly unique attention to detail.

The Sicilian logistics challenge: efficiency and flexibility

The customer, a leader in the production of young nursery plants for horticulture for many years, was faced with an increasing complexity in the management of its logistics, especially in relation to the movement of materials (fertilizers, packaging, seeds and other products necessary for plant growth), the flow of forklifts and transpallets, and storage in cold rooms. The challenge for Idromeccanica Lucchini, in this case, was to translate these requirements into a highly efficient, but also extremely lean and versatile industrial hub that would respond exactly to the demands, without the need for future modifications or adaptations.

We deployed our many years of experience in the logistics sector and in the construction of industrial facilities, proposing tailor-made solutions, designed to optimize every stage of the process, from the receipt of raw materials to the handling of finished products. Every detail has been thought out and designed to meet specific needs, with a focus on sustainability, safety and aesthetics, all key factors in ensuring quality of work, operational efficiency and institutional requirements.

Tailor-made engineering and logistics

A distinctive aspect of the project is the implementation of excellent carpentry, made of massive mechanical engineering elements, which represent a perfect mix of robustness and innovation. The 6,000 square-meters structure was designed to meet the most complex logistical requirements, in compliance with all necessary certifications.

Not only efficiency: every detail has been designed to integrate perfectly with the customer's vision, creating organized and easy-to-manage spaces where every material finds its place in a continuous and uninterrupted work-flow. Lucchini has reinterpreted the client's internal supply chain, creating a logistics system that allows optimal management of material handling, product storage and work-flow organization, in a context that complies with all local safety and environmental regulations.

A state-of-the-art industrial center: respect for the environment and the territory

One of the biggest challenges was to design a facility that respected the characteristics of the Sicilian territory, known for its landscape, seismic and water limitations. Lucchini was able to tackle these difficulties with agility, ensuring that the construction met all the requirements of the local institutions, obtaining the authorisation to build in a truly delicate context.

Rainwater harvesting, for example, was included in the design to ensure sustainable use of resources, minimizing environmental impact. Special care was also taken with the aesthetic aspect: the aim was to satisfy the needs of the client and the institutional bodies.

The result is a building that is not only functional, but also aesthetically pleasing.

Special details for ergonomic and functional spaces

But logistics, in this case, does not stop at the management of materials and industrial spaces (such as loading, unloading and internal partitions): Idromeccanica Lucchini has also created spaces dedicated to employee services, with a design that has included segmentations for office areas, meeting rooms, canteens and toilets. Every corner of the new industrial hub has been designed to improve operational efficiency, but also to ensure the comfort and safety of those who work there every day.

In particular, spaces for the storage of hazardous goods have also been provided, complying with the most stringent safety regulations and ensuring a safe and well-organized working environment.

Logistical innovation as an engine for growth

What has made and continues to make Idromeccanica Lucchini an ideal partner for this specific company is its ability to offer complete, integrated solutions that go well beyond the simple construction of plants and structures. Lucchini has been able to read and interpret the customer's strategic and operational needs with acumen, designing a logistics system that not only meets technical and regulatory standards, but is also designed to ergonomise and optimize workflows, ensuring efficient management of resources.

The construction of this new logistics hub is a concrete example of how innovation and engineering can turn challenges into opportunities.

Thanks to Idromeccanica Lucchini's vision and expertise, we have not only built a state-of-the-art facility, but also created an ‘augmented’ working environment, where logistics and operational efficiency come together to ensure maximum quality and productivity, as well as sustainability and efficiency.