Let's talk again about Abruzzo region, where our long experience in nursery facilities is finding more and more room for application. The project in which we have been involved is the result of a long-standing collaboration with one of the most established companies in the nursery sector for young outdoor plants in Italy, for which we have put in place highly specialized solutions capable of meeting the challenges of an ever-changing global market.

A greenhouse designed for excellence

We built a new greenhouse complex with a first step of over 5,000 square meters and an extraordinary renovation of three blocks, covering a total of over 11,000 square meters.

The three existing blocks underwent an extraordinary renovation that involved raising the structures and reinforcing them to improve their structural strength - also optimising the cultivation and work requirements, which are essential for the smooth running of nursery activities.

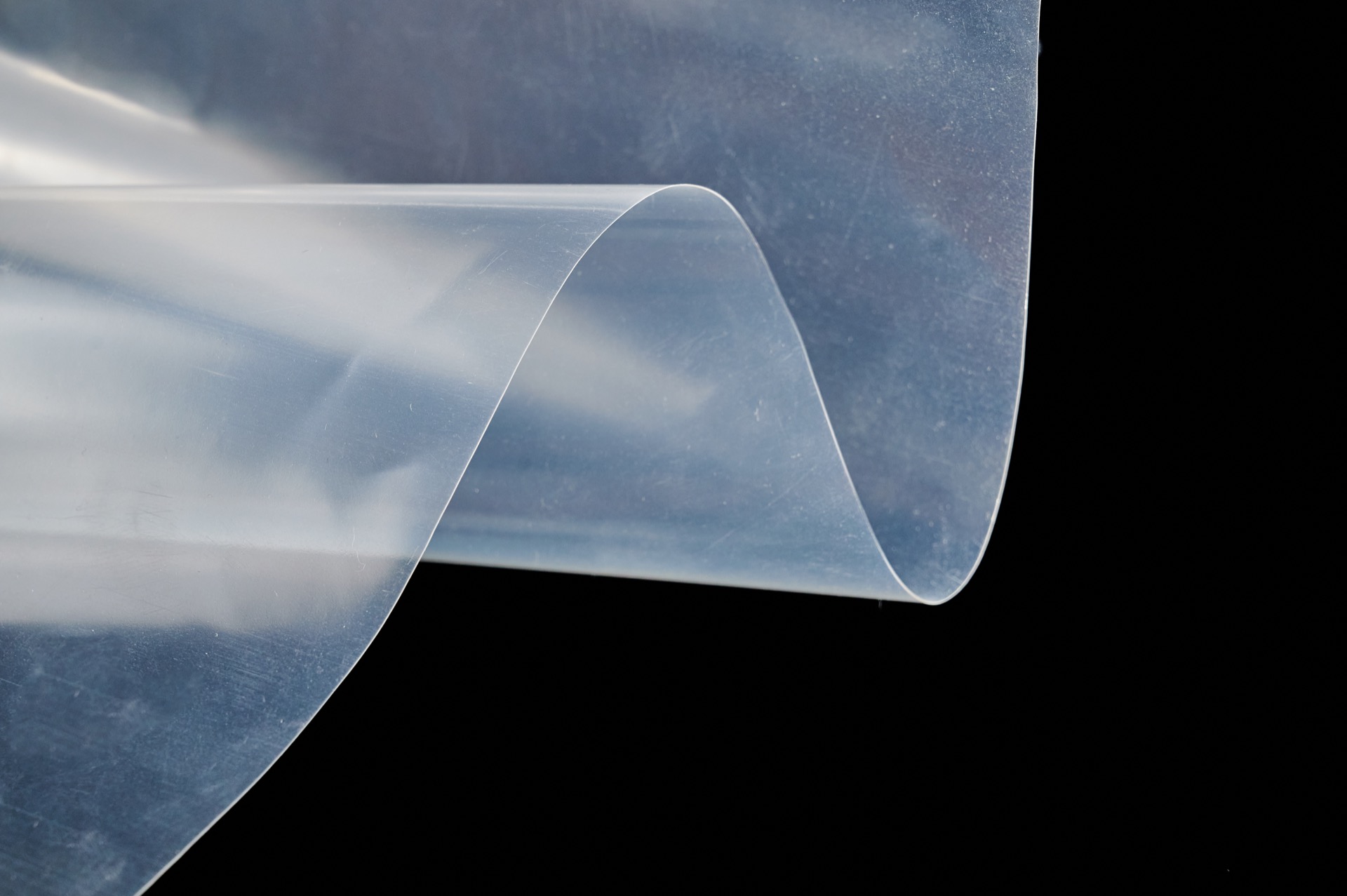

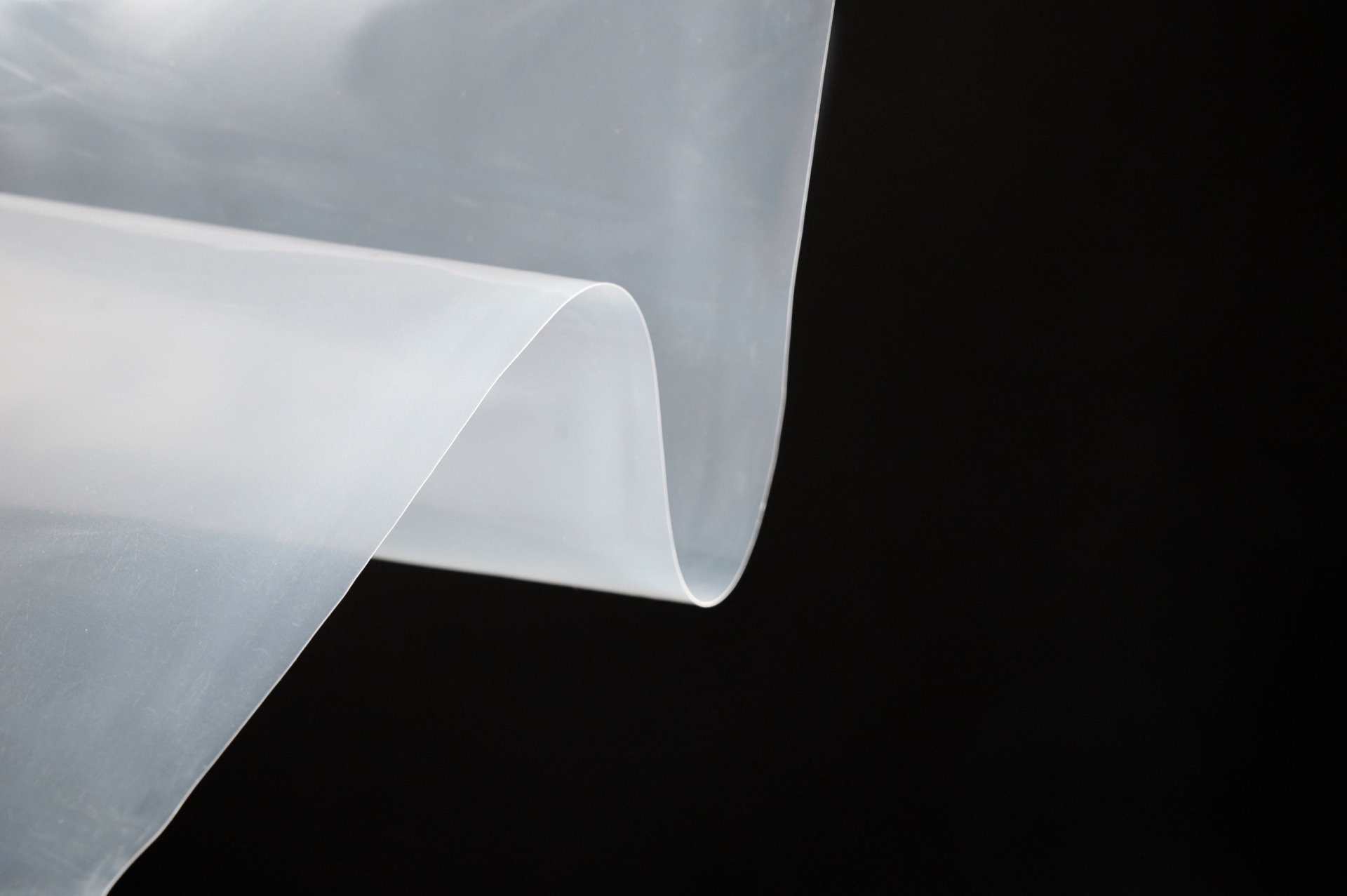

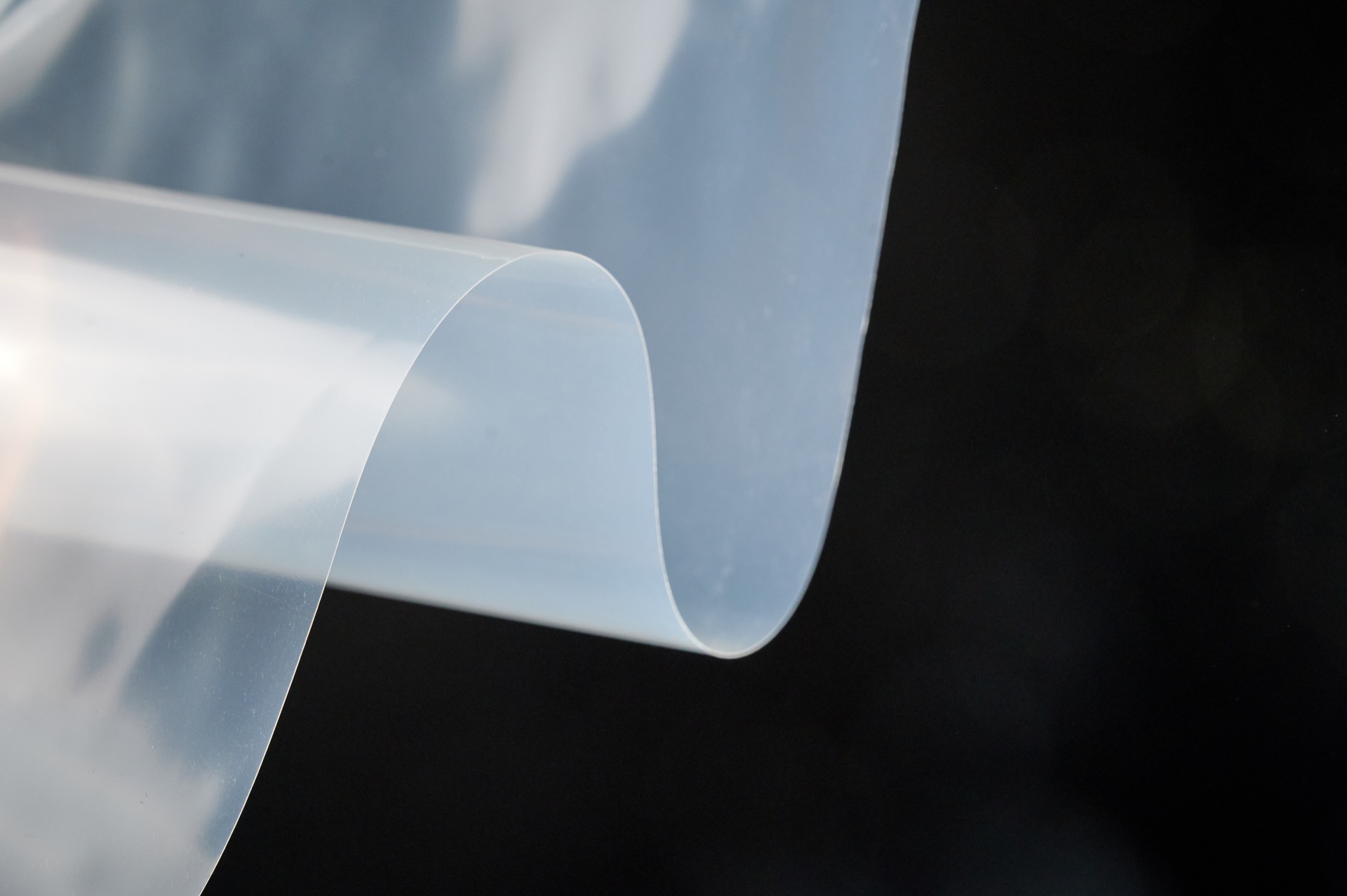

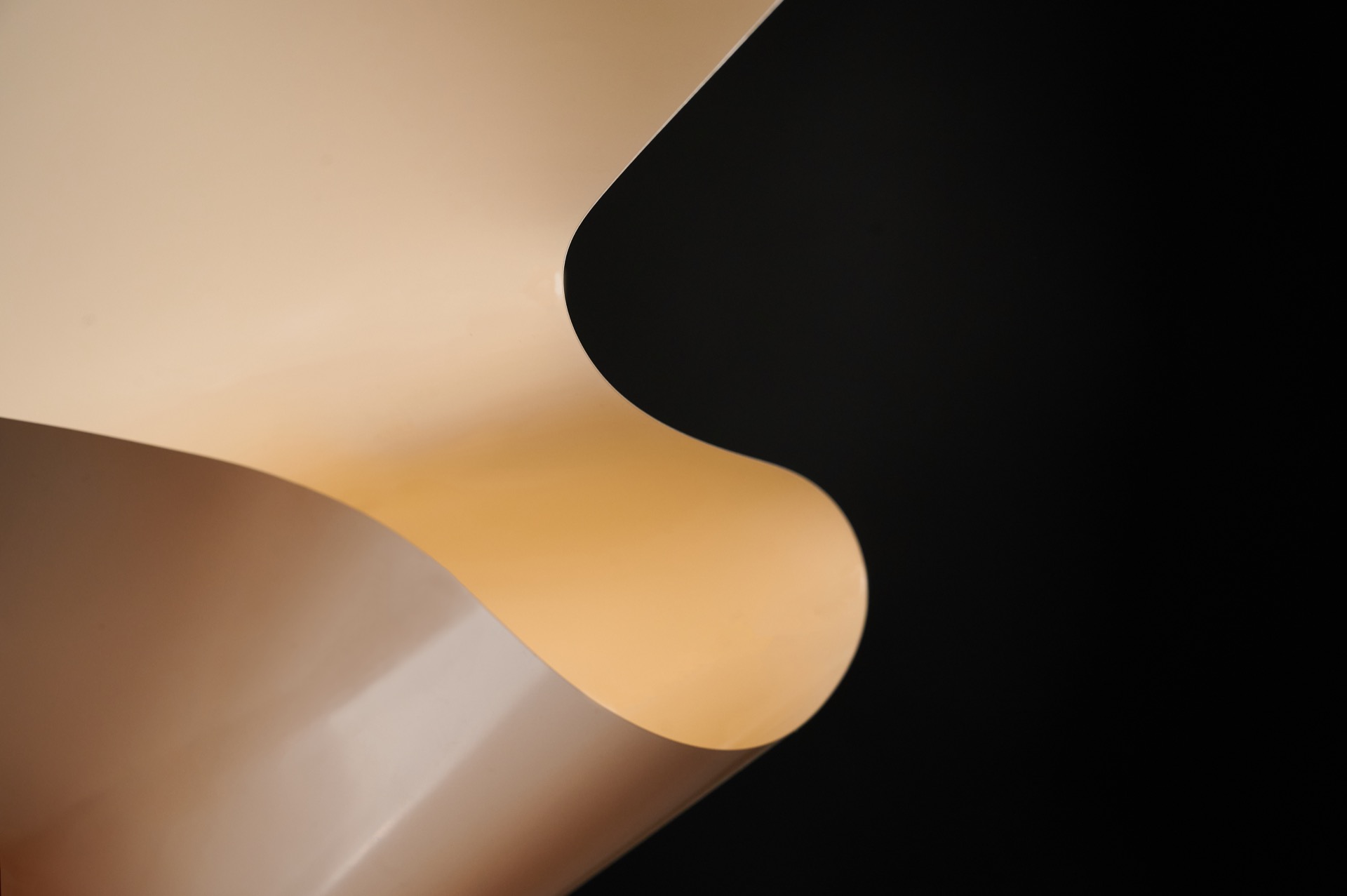

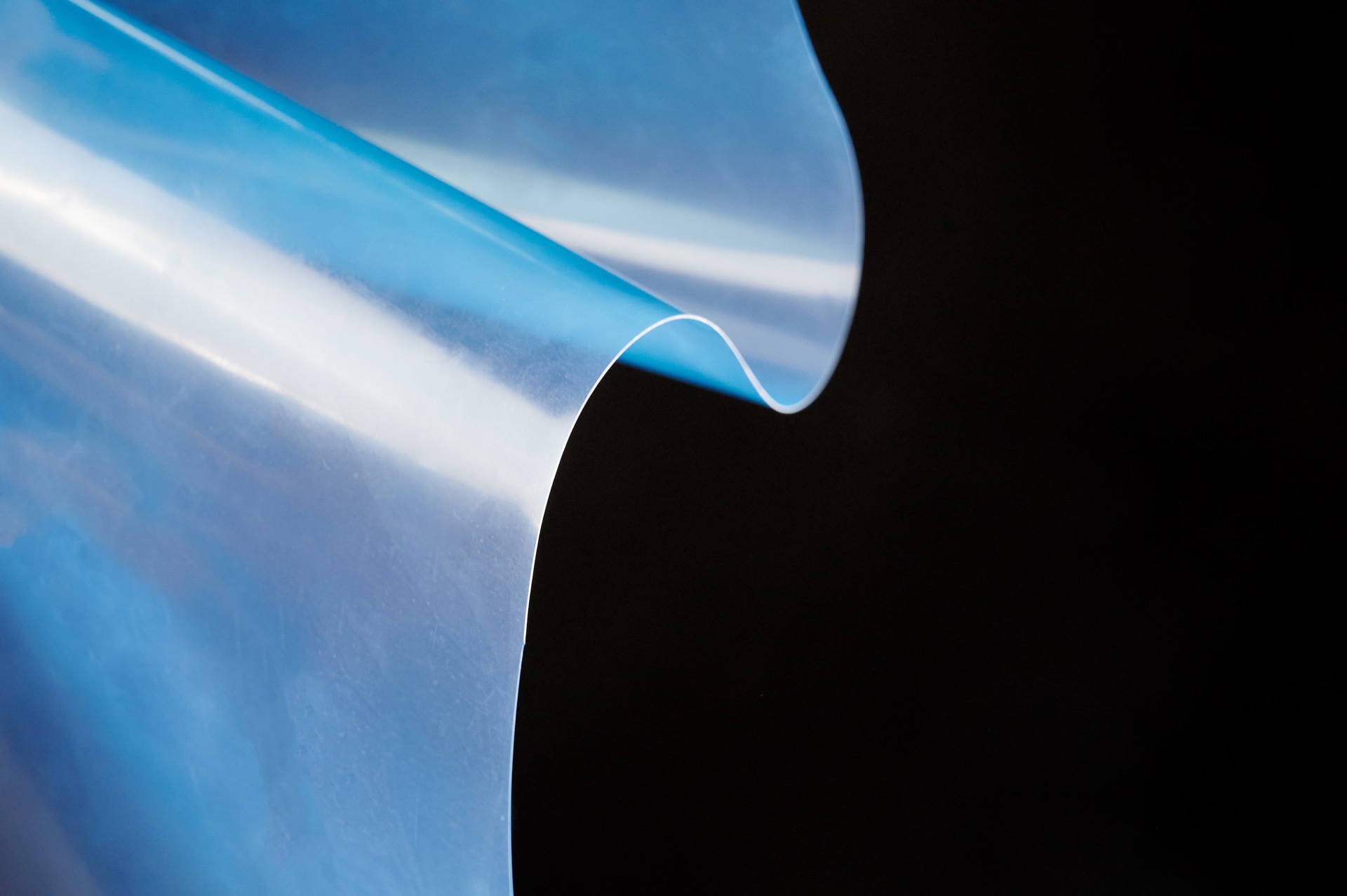

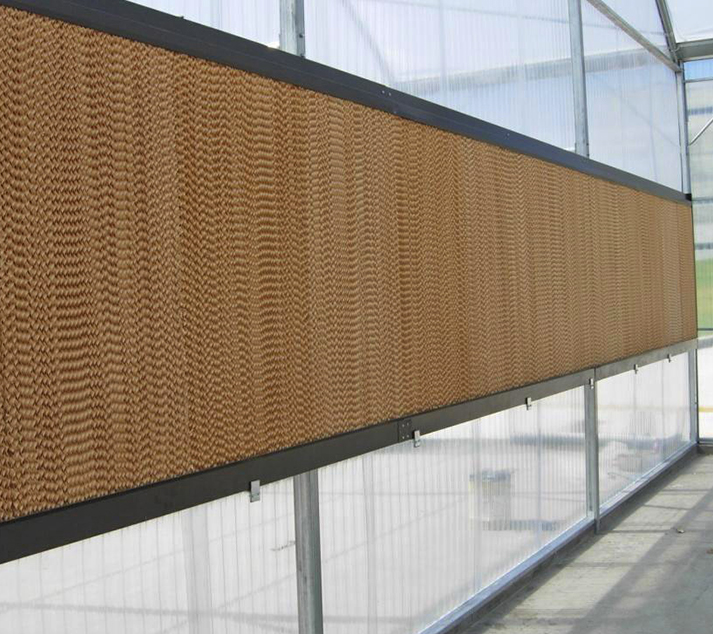

This upgrade allowed the installation of a cover-cover system, a solution that allows the greenhouse to be used seasonally, optimising its performance in both summer and winter.

This ‘hybrid’ greenhouse combines seasonal expedients and cost reduction, also helping to improve the greenhouse's microclimate, which is vital for plant growth and, therefore, for customer demand.

The greenhouse for ‘flexible’ nurseries

In the nursery sector, flexibility is a key element. Greenhouses have to respond to very specific needs, with cultivation of plants that require different interventions in the initial period, in order to be strong and robust when they continue their life outside. For this reason, in our new project (of over 5,000 square meters), we have created a greenhouse with ideal dimensions and structures to guarantee optimal climatic conditions for young plants all year round.

Every detail was studied to create a healthy and controlled environment, regulating (for instance) humidity and temperature, adapting them to respect the biological needs of the plants, both those that require a certain type of stress to grow and those that need a more constant and balanced environment.

The value of predictive data

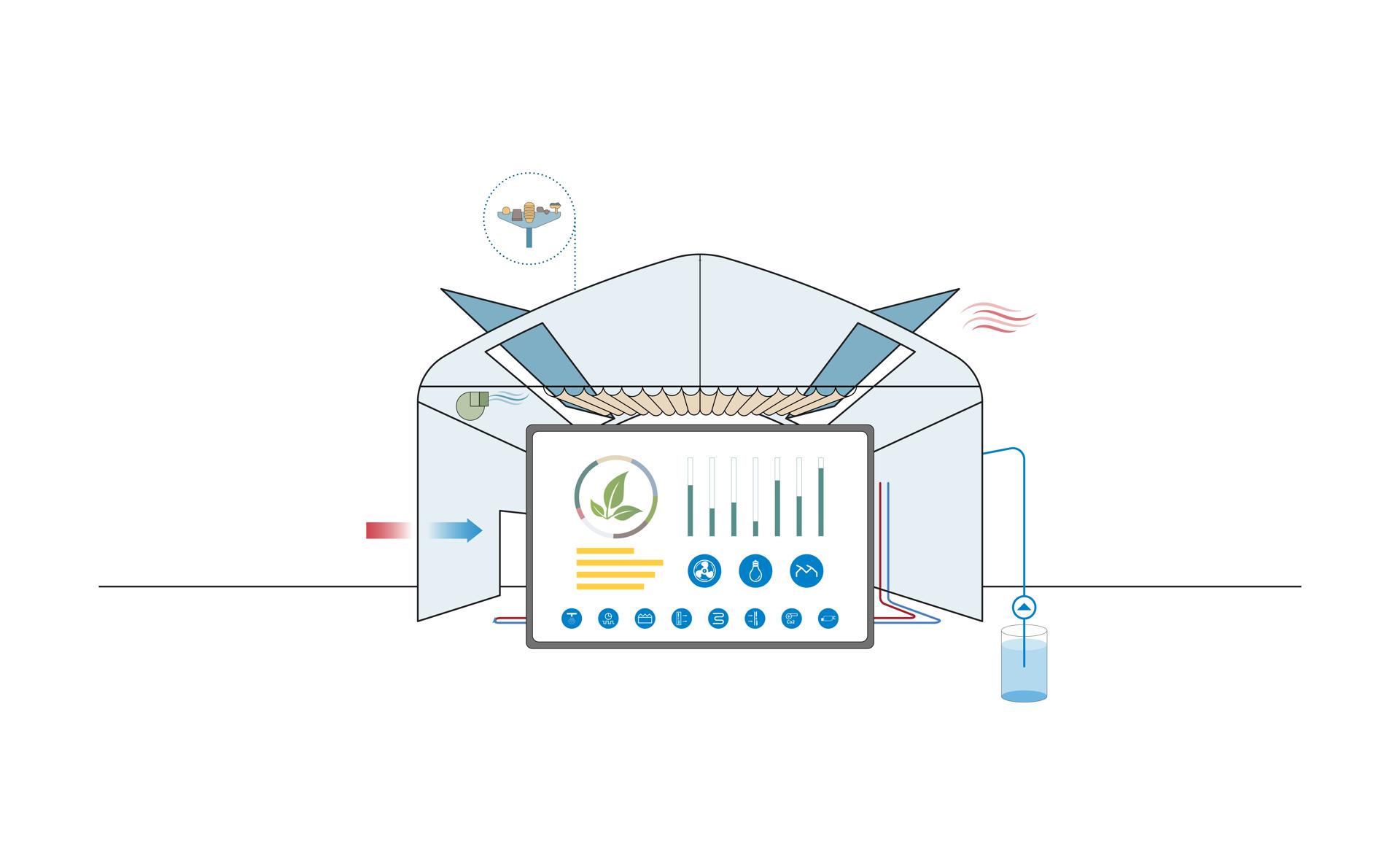

The real innovative component of this project concerns the constant control to which the plants are subjected.

The entire production process, in fact, is monitored and optimised thanks to the use of data management systems that allow us to predict the behaviour of the plants in different environmental conditions.

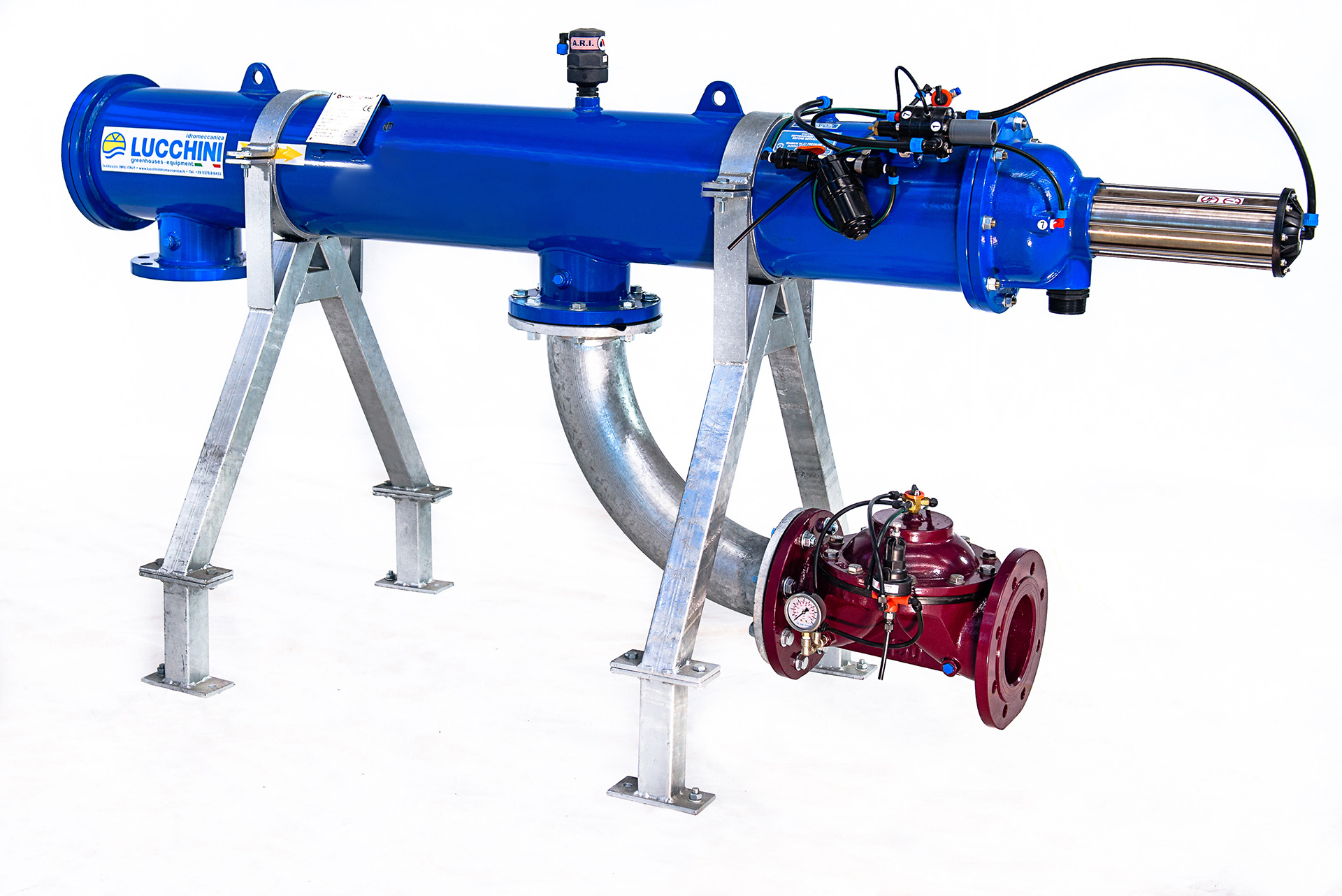

The OPI system used by Lucchini, in fact, is used to monitor the parameters collected during cultivation in the greenhouses to generate (thanks to the support of Artificial Intelligence) predictive models capable of suggesting safe and proven practices to improve production, product quality and processing.

Thanks to this new paradigm for data-driven agriculture, it is possible to cultivate efficiently, economically and sustainably - also being able to predict and prevent contingencies due to climate change.

This predictive monitoring - later also integrated in the renovated greenhouse - is one of the many facets of Idromeccanica Lucchini's quality work, which significantly differentiates us from our competitors, as it enables us to prevent serious damage and intervene quickly, creating a true ‘biological retrofitting ’, improving resistance to plant diseases in a natural way and reducing the need for invasive chemical treatments.

A partner for perpetual innovation

Using our ability to combine research, flexibility and sustainability, Idromeccanica Lucchini designs and implements each project to meet concrete customer challenges, offering tailor-made solutions that go beyond expectations.

In an increasingly competitive global market, our ability to adapt quickly to change and guarantee concrete results is what sets us apart and gives us value.

We are building a future where greenhouses and plants not only meet the needs of nurseries, but are also able to meet the challenges of long-term sustainability.