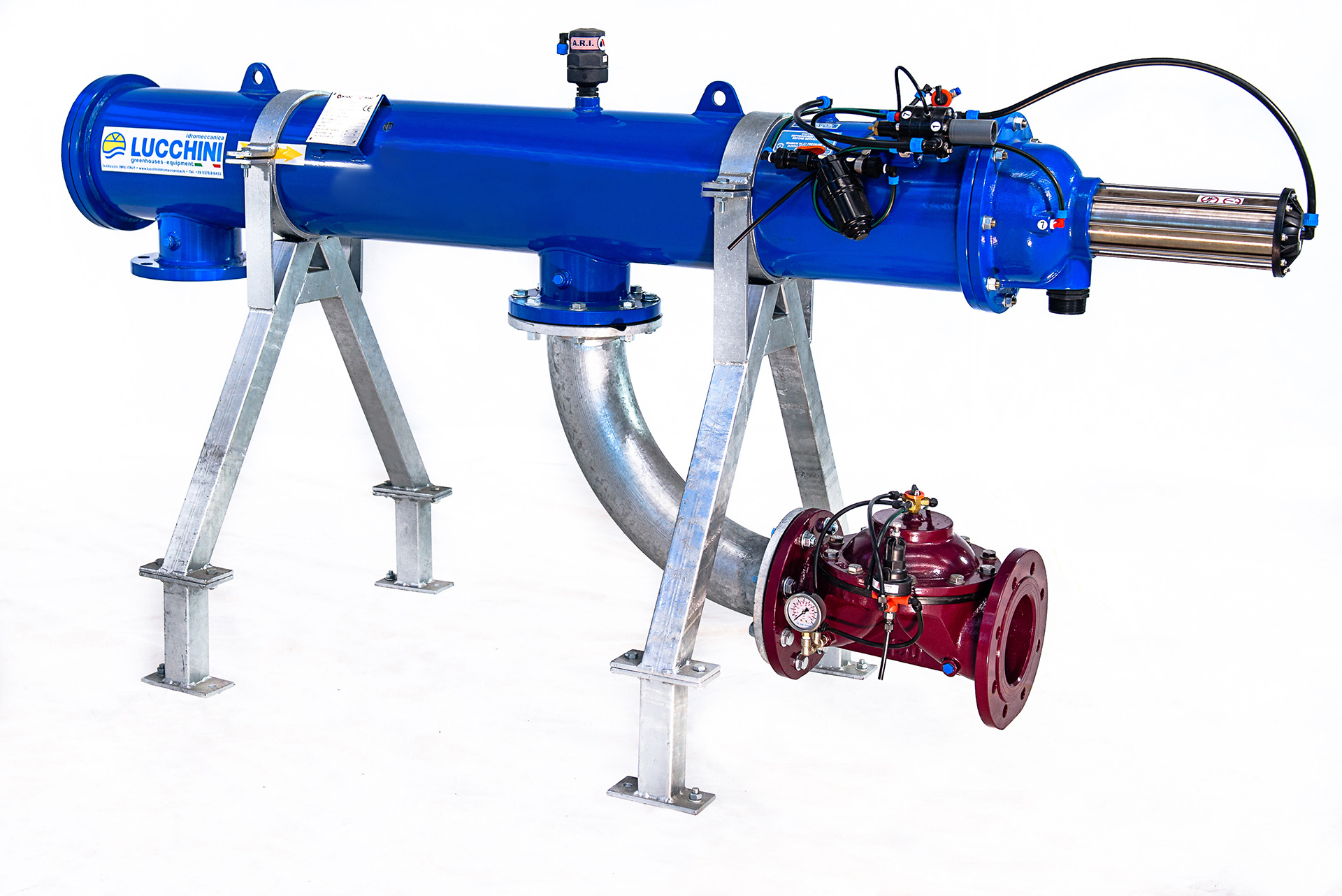

Precision, customisation and control are the key words followed by Lucchini Technical, the technical department of Idromeccanica Lucchini. The company takes care of every project from the design phase to its implementation and all corporate guidelines promote environmental and energy sustainability.

Ecological design

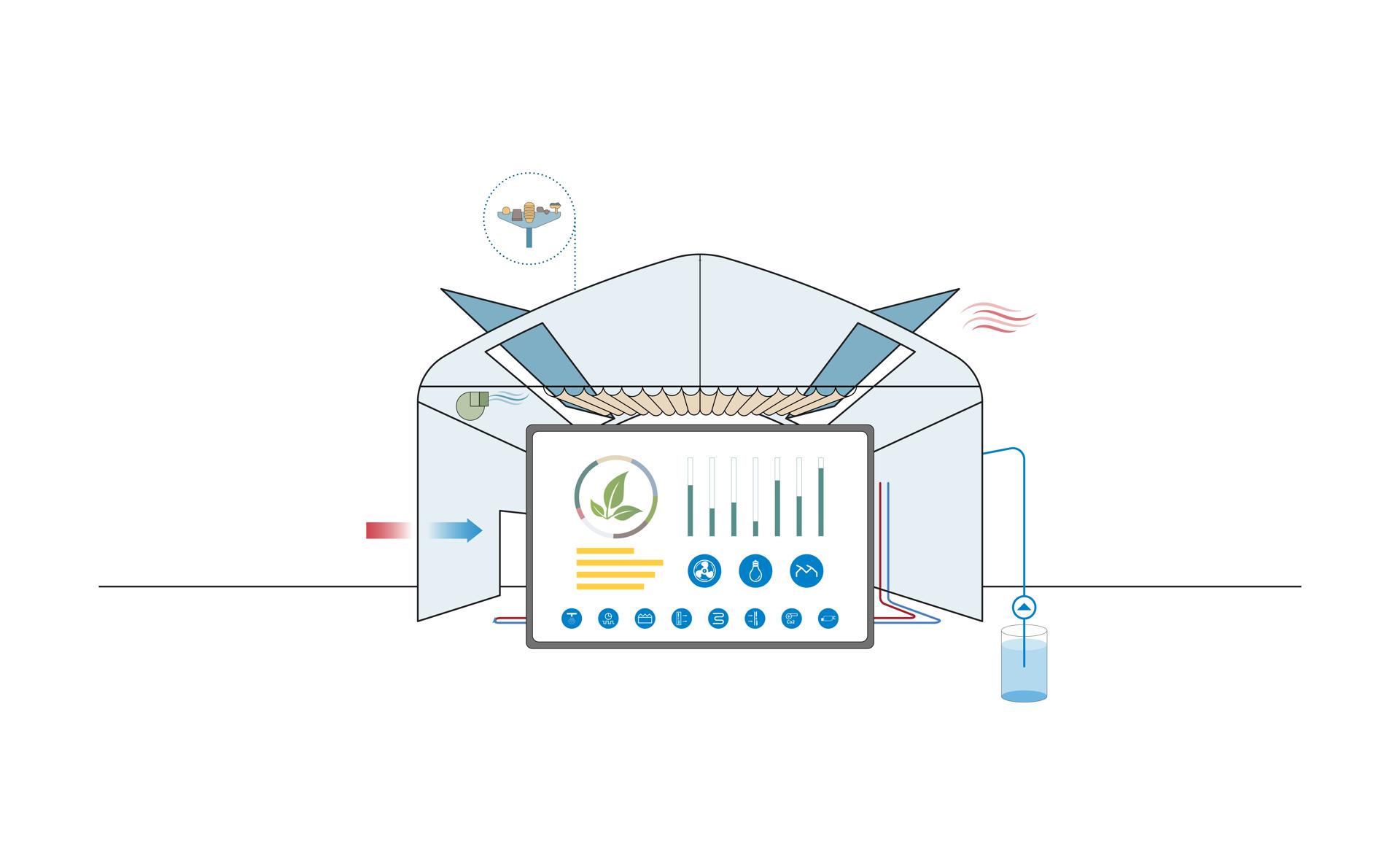

The recent global energy crisis and the increases in the prices of raw materials and transport have led Idromeccanica Lucchini to start new working processes even more aimed at rationalizing resources. The calculation of the materials to be used for production and installation is carefully established at the beginning. In this way, surpluses and waste, unnecessary transport costs and consumption of energy resources are avoided. Calculations are carried out taking into account the percentage of surplus material that may be necessary to solve last-minute problems during the installation phase. In addition to materials, software is also designed and calibrated to reduce energy consumption at the hardware level. Valuable resources such as water and nutrients for plants are also carefully controlled right from the initial study and design stage.

Idromeccanica Lucchini’s research on the Agrivoltaic industry

Lucchini Technical is working on the agrivoltaic technology to promote eco-sustainability practices. This is a system that can conjugate agriculture and clean energy production. The goal is to combine crops that do not require excessive sunlight and photovoltaic systems under which it is possible to sow seeds, or use photovoltaic films to cover greenhouses. Thus, it will be possible to use hectares of field covered by photovoltaics without wasting the land underneath.

Providing the customer with a complete engineering service

Lucchini Technical focuses on increasing customer satisfaction. Technicians are constantly trained and updated on the latest technologies to meet new customers’ needs with customized solutions. Consequently, Idromeccanica Lucchini provides customized solutions for every need such as: soil type, orography, legal constraints or specific customer wishes. Each structure is custom-designed by modifying existing products or by creating systems from scratch based on the customers' specific requirements.

Idromeccanica Lucchini’s workflow is as follows:

- Sales contact with customers

- Project drafting by Lucchini Technical

- Installation supervised by Lucchini Technical

- Inspection and testing

- Any amendments and adaptations

- Training and post-sales assistance service

More precisely, Lucchini Technical writes a preliminary technical-economic proposal after the sales contact. If needed, appropriate revisions are made before arriving at the executive project. This is shared internally and screened by all departments. At this point, a bill of materials is created and materials are purchased. Then, it is time for the production and assembly phase on site. Throughout the entire process, Lucchini Technical ensures adherence to deadlines in order to comply with the requirements of state and European regulations regarding tax incentives or other benefits that can significantly reduce costs. Each project is unique and differs from routine operations. Lucchini Technical carries out the most successful project offering specific solutions for specific requirements.