California is one of the most populous and richest states in the entire United States and the demand for quality food is obviously very high. With the exception of the coastal strip, however, the climate of California, despite being suitable for agriculture, has typical and insidious climatic variability that require high-tech solutions to ensure the growth of nursery seedlings.

A project in great style

East of San Francisco, in the Central Valley area of California, Idromeccanica Lucchini has developed a project for the cultivation of tomato seedlings intended for processing for the canning industry. The project, which lasted for years, allowed the construction of entire hectares of nursery greenhouses for tomato seedlings. The nursery, which has been in existence for 20 years, has seen a great expansion since 2015, when Idromeccanica Lucchini began the construction of greenhouses for a total area of about 3 hectares. Since 2019, other greenhouses have been installed, for a further 3 hectares, updated with the "cover discover" technology, essential for the management of the seedlings in the period from February to April. The latter plant could also grow further in the near future.

The tomato processing cycle

The processing cycle for the tomato plants starts from December and runs until June. The greenhouses operate 6 months a year and produce resistant and robust seedlings which, only subsequently, are planted in the open field (generally between February and June) for the production of the fruit. At the beginning of the cycle the seeds are placed in the germination chambers to be then taken to the greenhouse where the actual growth cycle of the plant takes place.

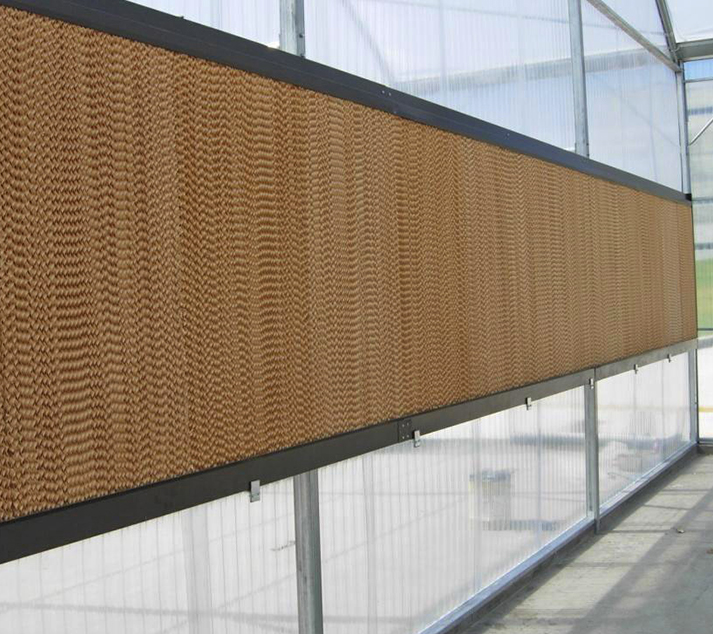

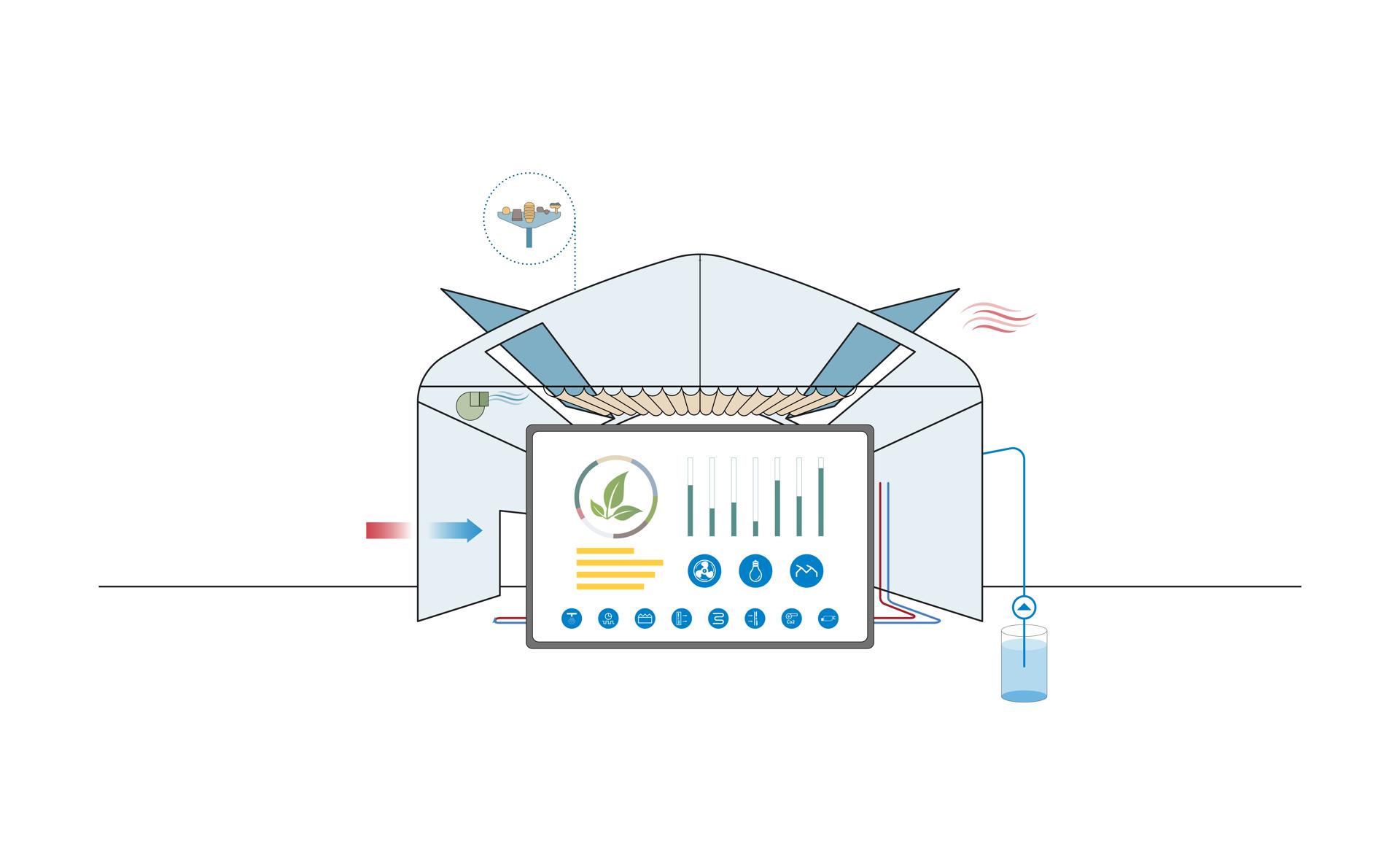

A specific air conditioning

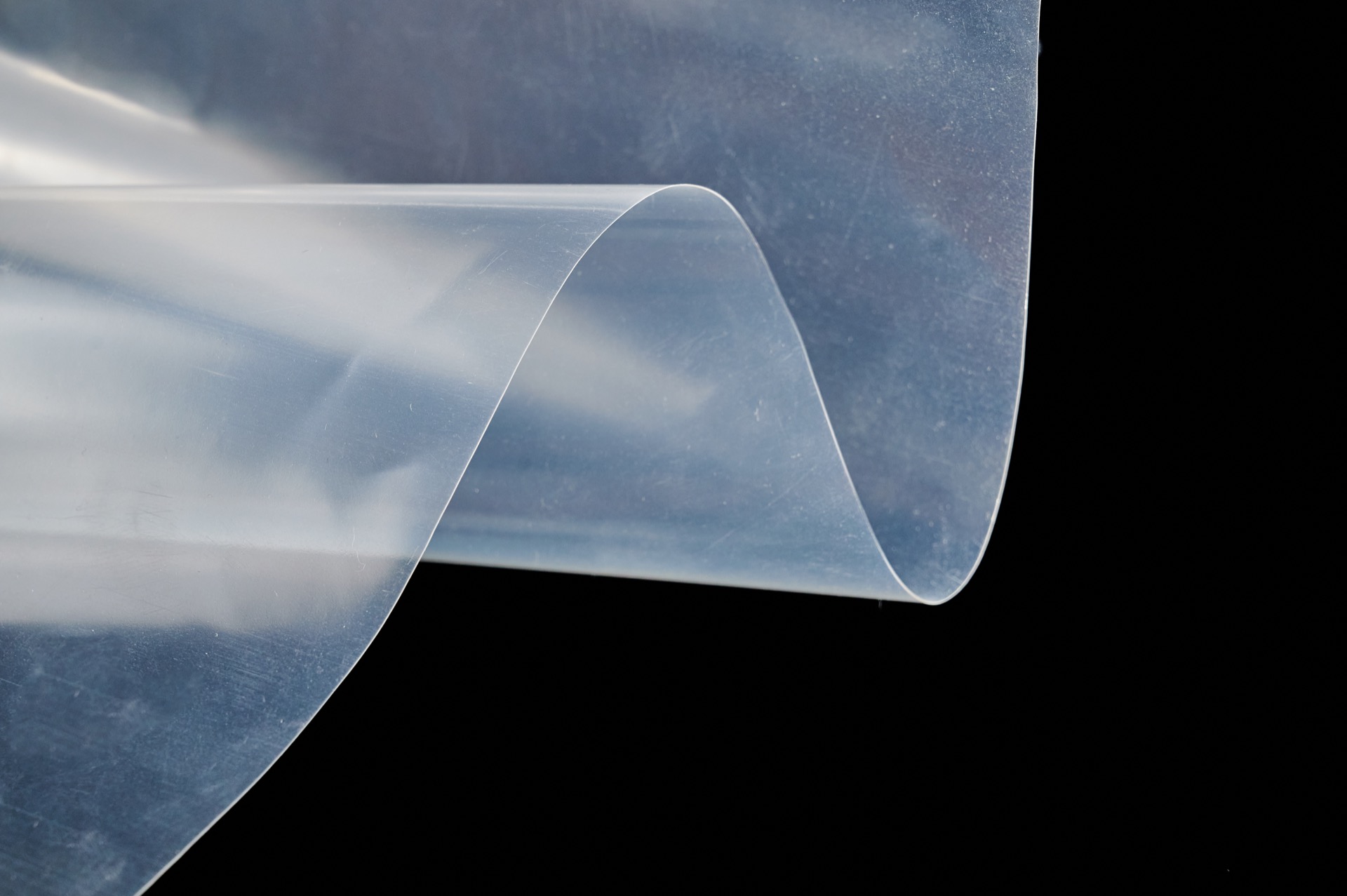

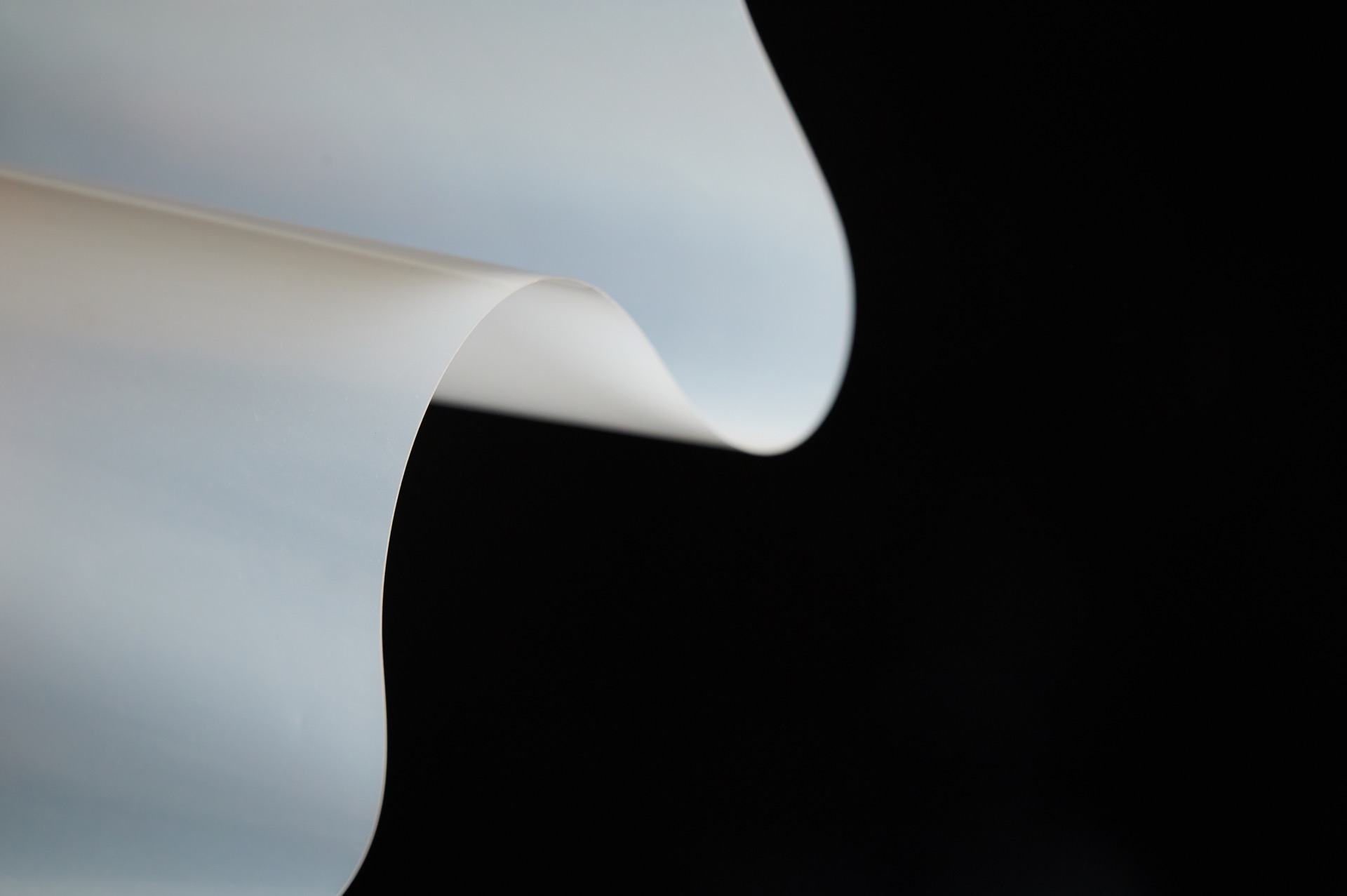

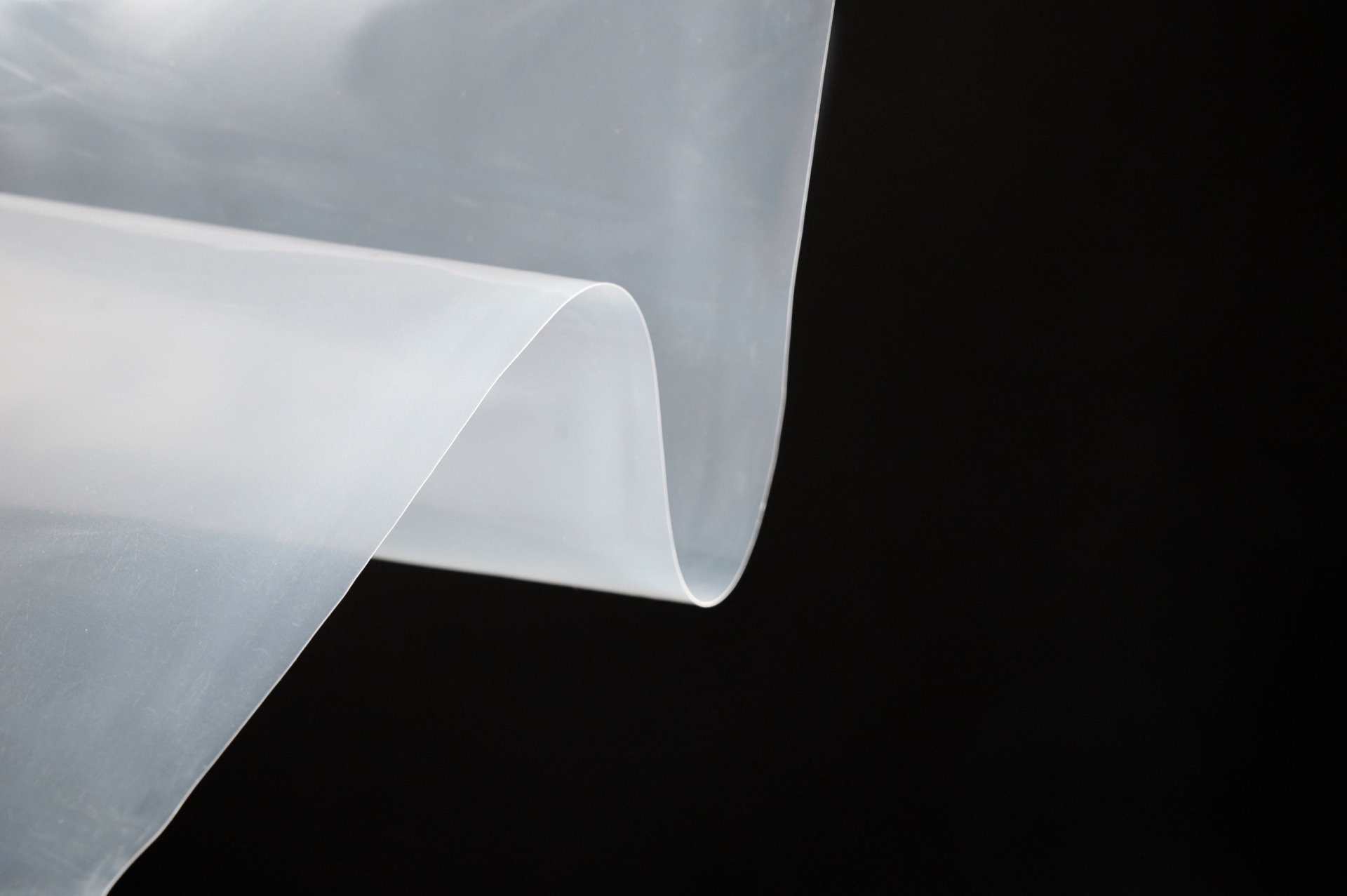

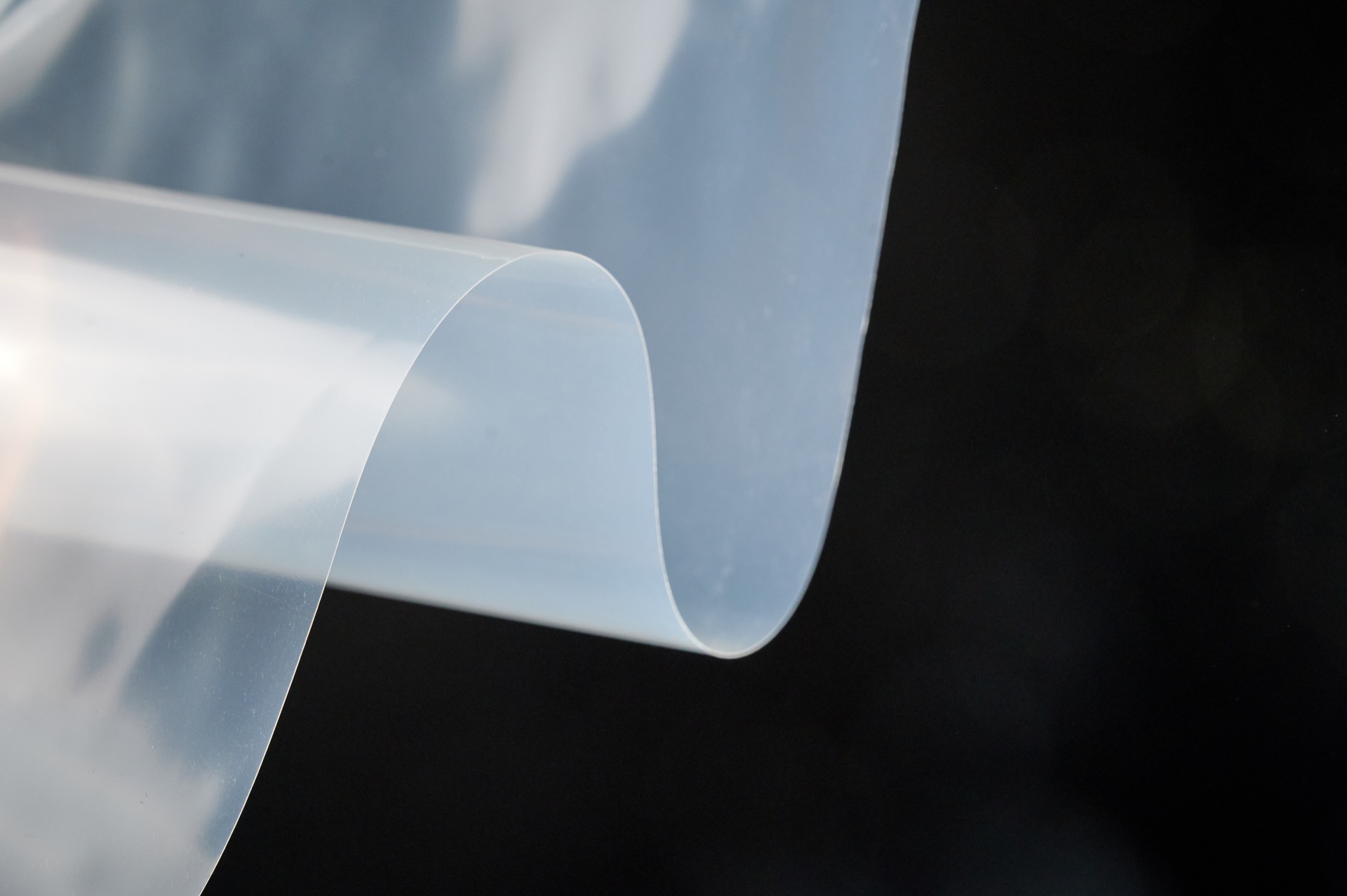

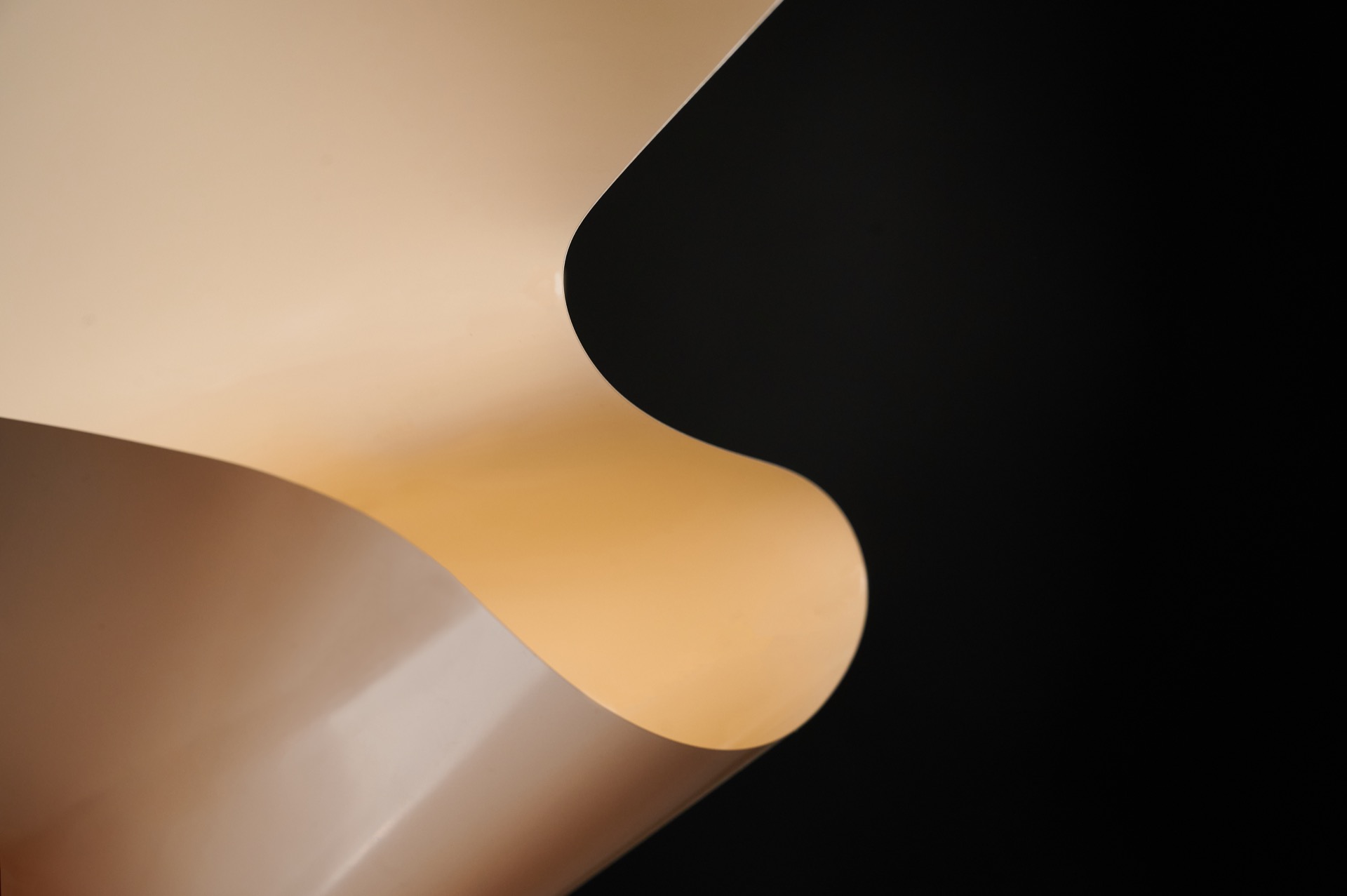

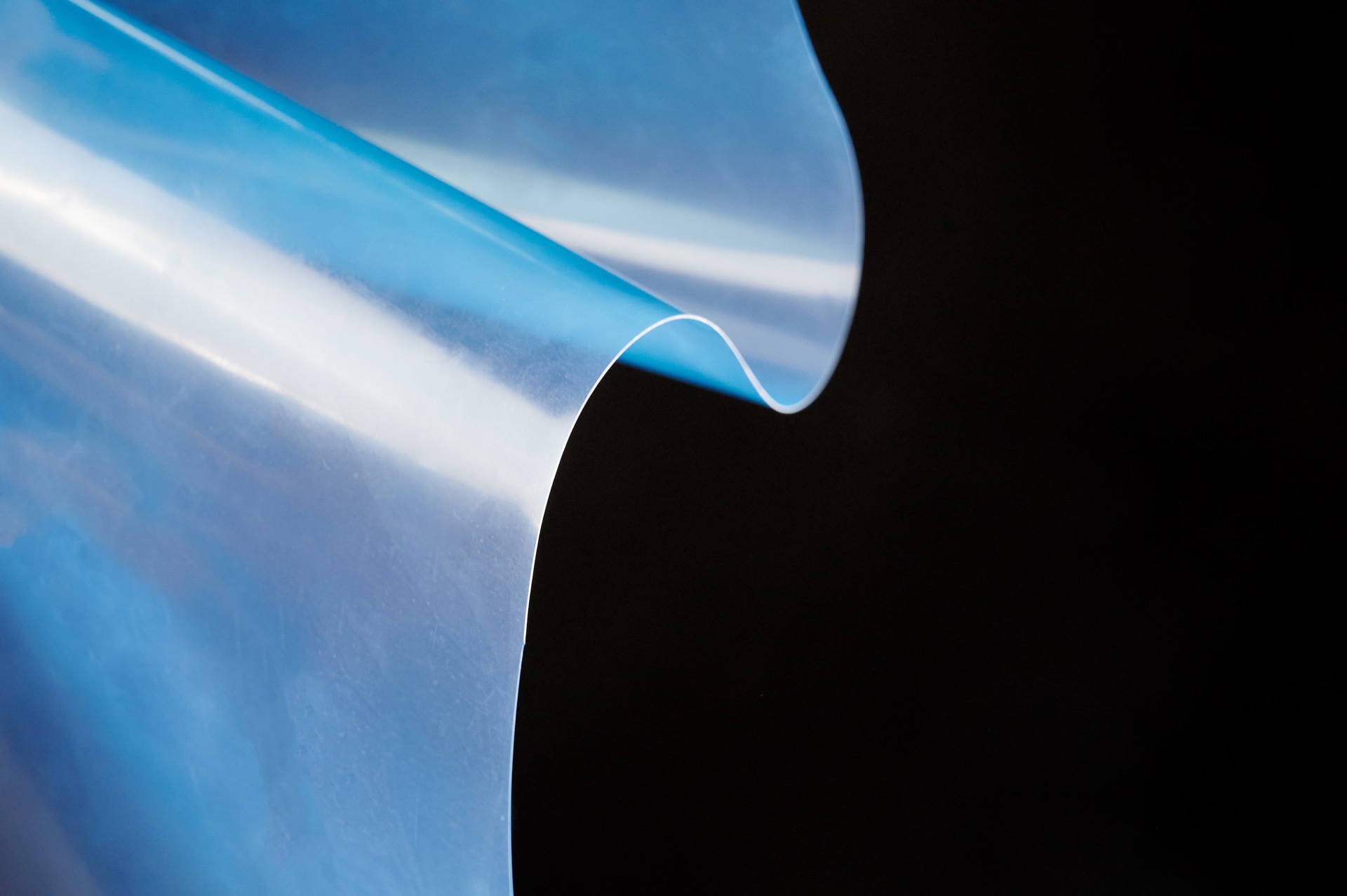

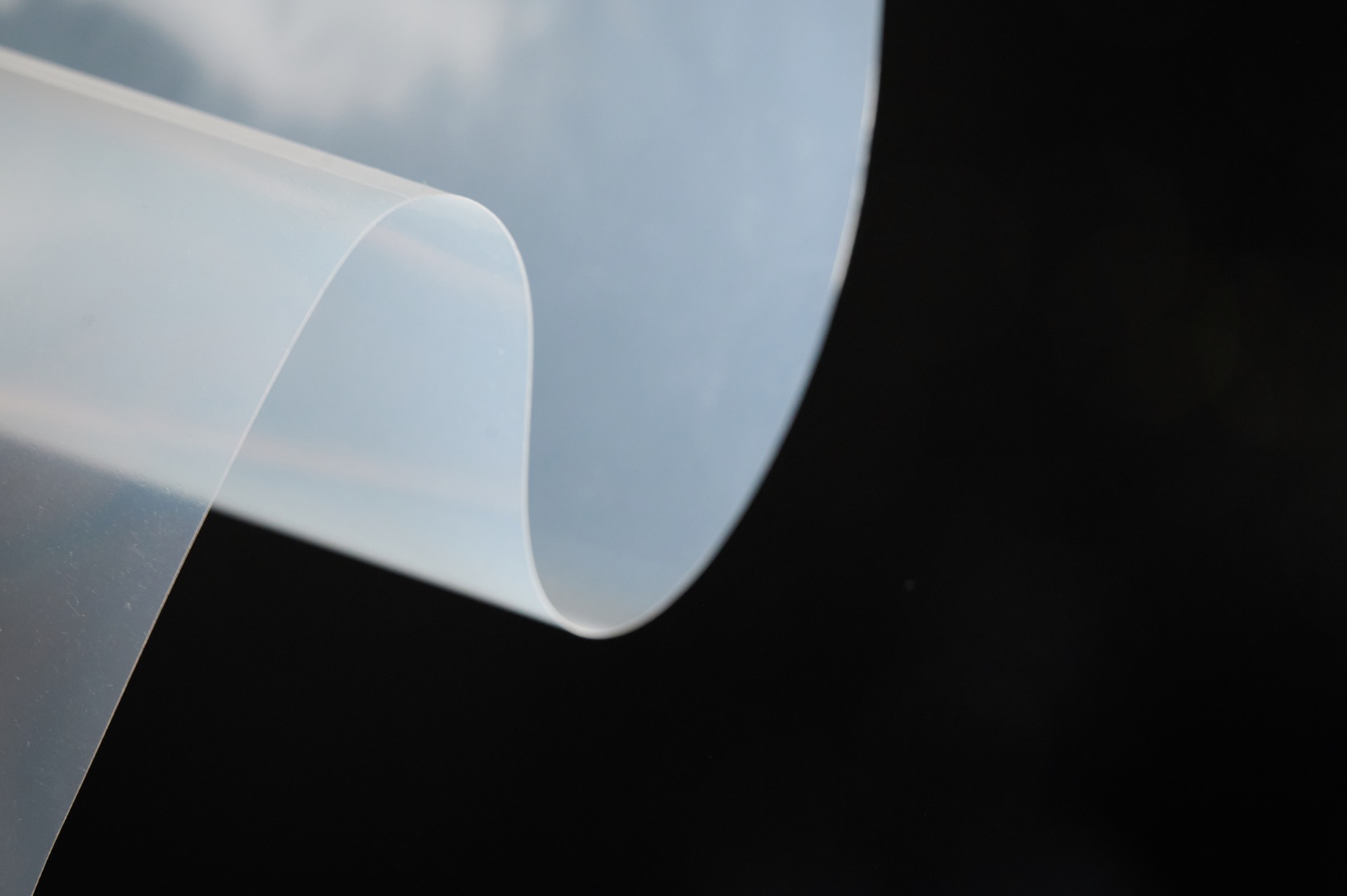

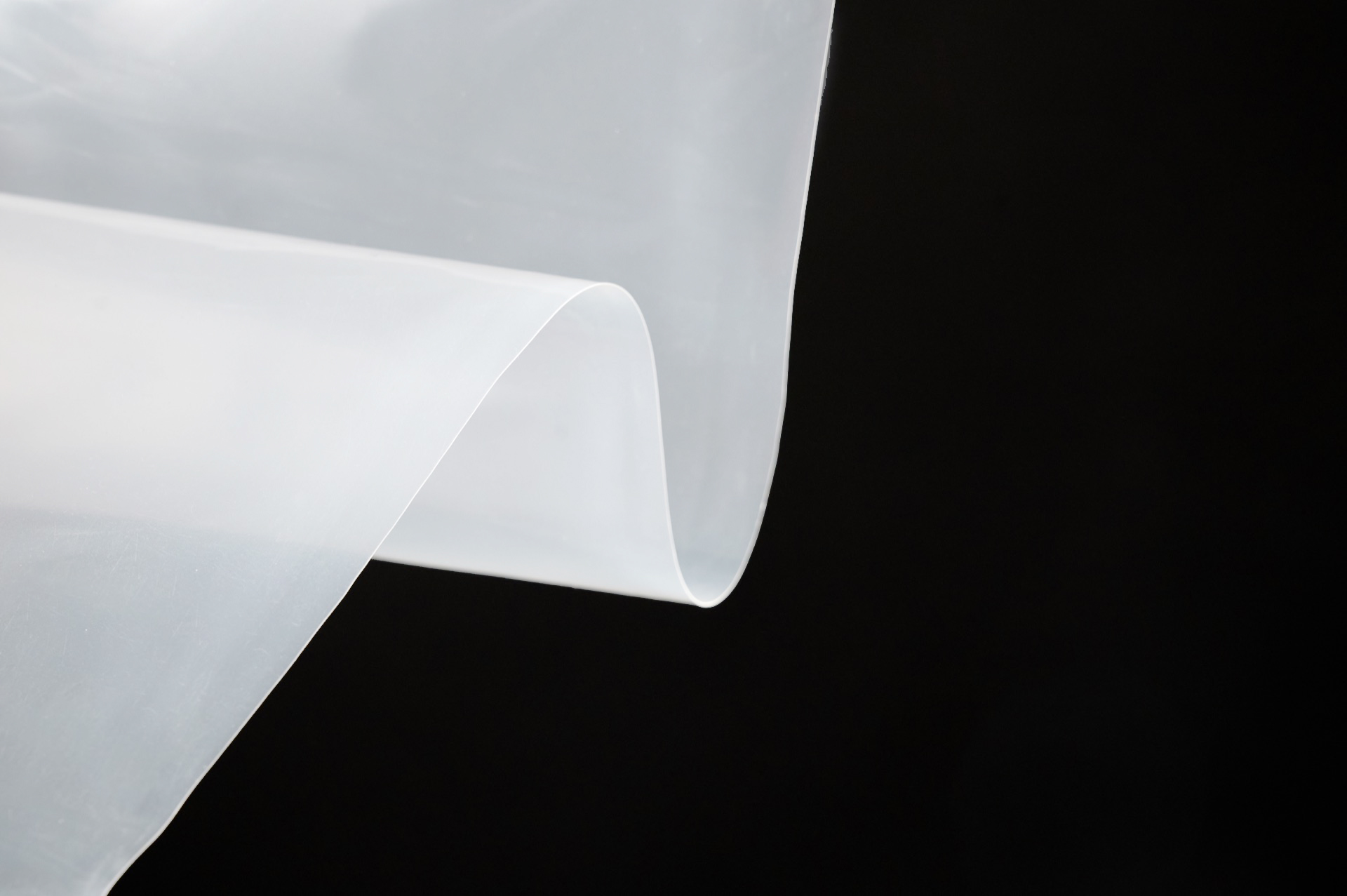

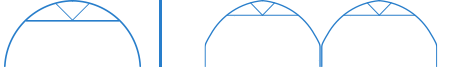

In the Central Valley, in the period from December to June, the climate suffers from a wide variability: the winters are very cold and the summers are hot and, for this reason, the greenhouses must be specifically air-conditioned. In summer, the maximum temperatures are very high and there is a need for ventilation inside the greenhouse. In the first months of spring, however, you can witness intense frosts and colds. The greenhouses built by Idromeccanica Lucchini present solutions to quickly cover the roof during the period characterized by cold temperatures or open it to allow the seedlings to carry out the second growth cycle in the open air. To better regulate the internal temperature, a ventilation system has been provided with openings, both at the ridge and on the perimeter, equipped with automatic movement systems. For further insulation, the greenhouses have a double inflated roof covering that allows the temperature to be kept constant in both summer and winter. During the winter season, however, the greenhouses are heated with a special system that automatically controls the climate to maintain the optimum temperature.

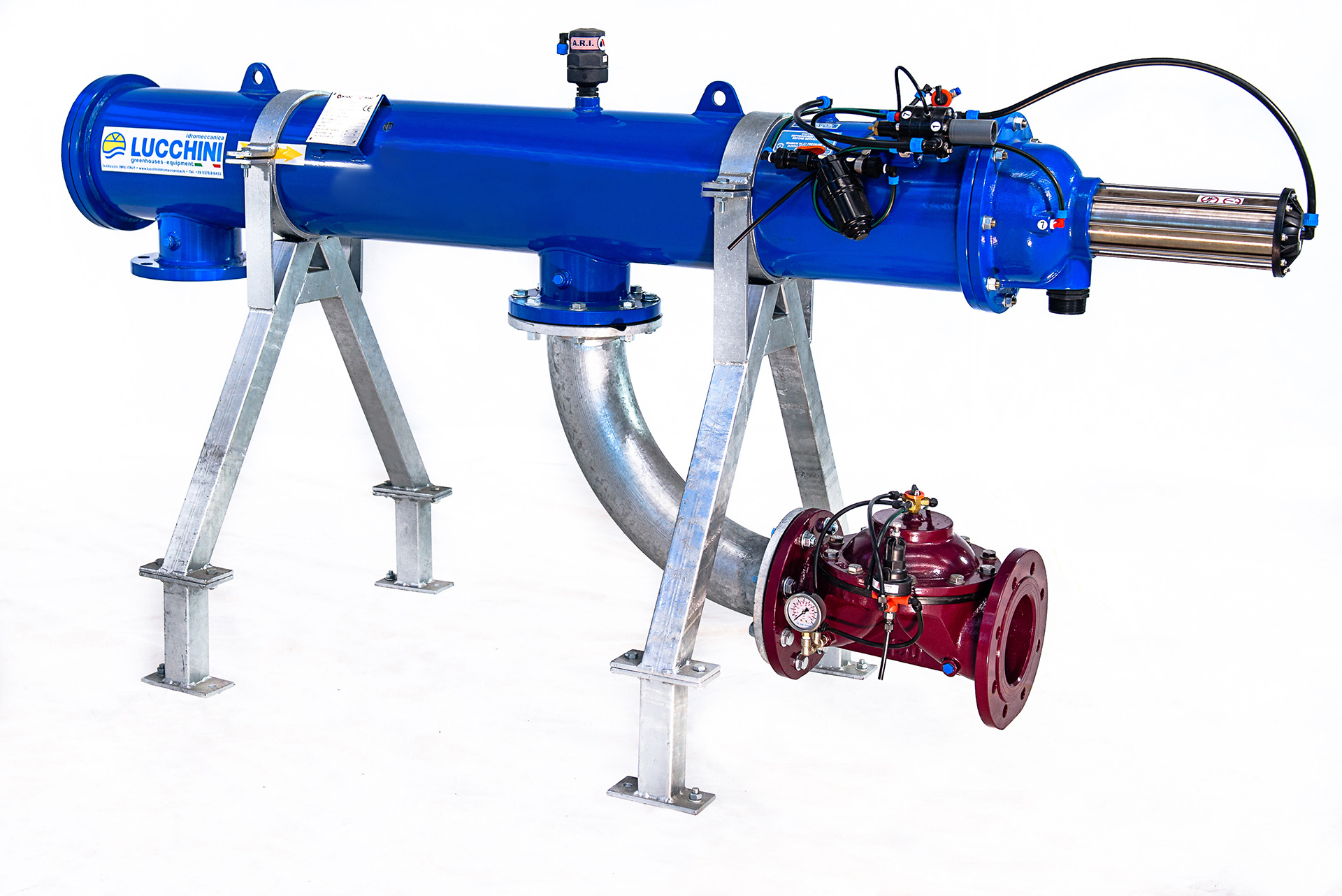

Handling and irrigation

The cultivation of tomato seedlings intended for canning processing is done 80 cm from the ground on trays where the seedlings are placed. The trays slide on aluminum T-rails with galvanized supports very useful for handling crops according to the processing needs. Irrigation is achieved through mobile bars that spray water evenly on the trays. Obviously, the irrigation is automated and the times can be programmed and optimized as needed.

A challenge and an opportunity

Building such a large plant in such an important area of United States was a logistical and technological challenge for Idromeccanica Lucchini. All the materials, in fact, came from Italy and were transported and assembled on site by Idromeccanica Lucchini in what is one of the largest and most important nurseries in all the "States". In addition to the difficulties due to the logistic aspect, Idromeccanica Lucchini had to know how to adapt to the various American regulations and had to find, from time to time, the technological solutions suitable for the typical climate of the Californian desert. However, the project represents an important strategic asset, which allows Idromeccanica Lucchini to lay the foundations for future expansions in the rich American market. The huge expansion of greenhouse cultivation is already leading to a new project near Sacramento. The project will be characterized by a strong automation of the systems that will guarantee a mechanical handling of the pallets to make the greenhouses more and more independent from the staff. The problems due to the pandemic and the high cost of labour in the United States, in fact, require automation capable of making up for the lack of workforce.