Kirgizistan Project

During the spring of 2020, Idromeccanica Lucchini was involved in a new international project aimed at increasing the yield of tomato cultivation in an area of Kyrgyzstan on behalf of Tomag KG. The Kyrgyz factory is able to work and process 750 tons of fresh product per day for the production of tomato concentrate.

The tomato growing area covers 780 hectares of open field. The main objective of the project was to increase the yield of fruit for seedlings. The climate of the region does not allow harvests considered satisfactory for the company.

Strategy for tomato plants

Idromeccanica Lucchini intervened with its agronomists, technicians and designers and, analyzed the situation, has devised a system that provides for the germination and growth of plants in the greenhouse. Only at a certain point of their growth, the seedlings are then transplanted into the open field. The plants, so stronger and better nourished, are therefore able to resist more to the atmospheric agents and to produce a greater quantity of fruit of better quality than the plants born and grown directly in the field.

Greenhouses Structure

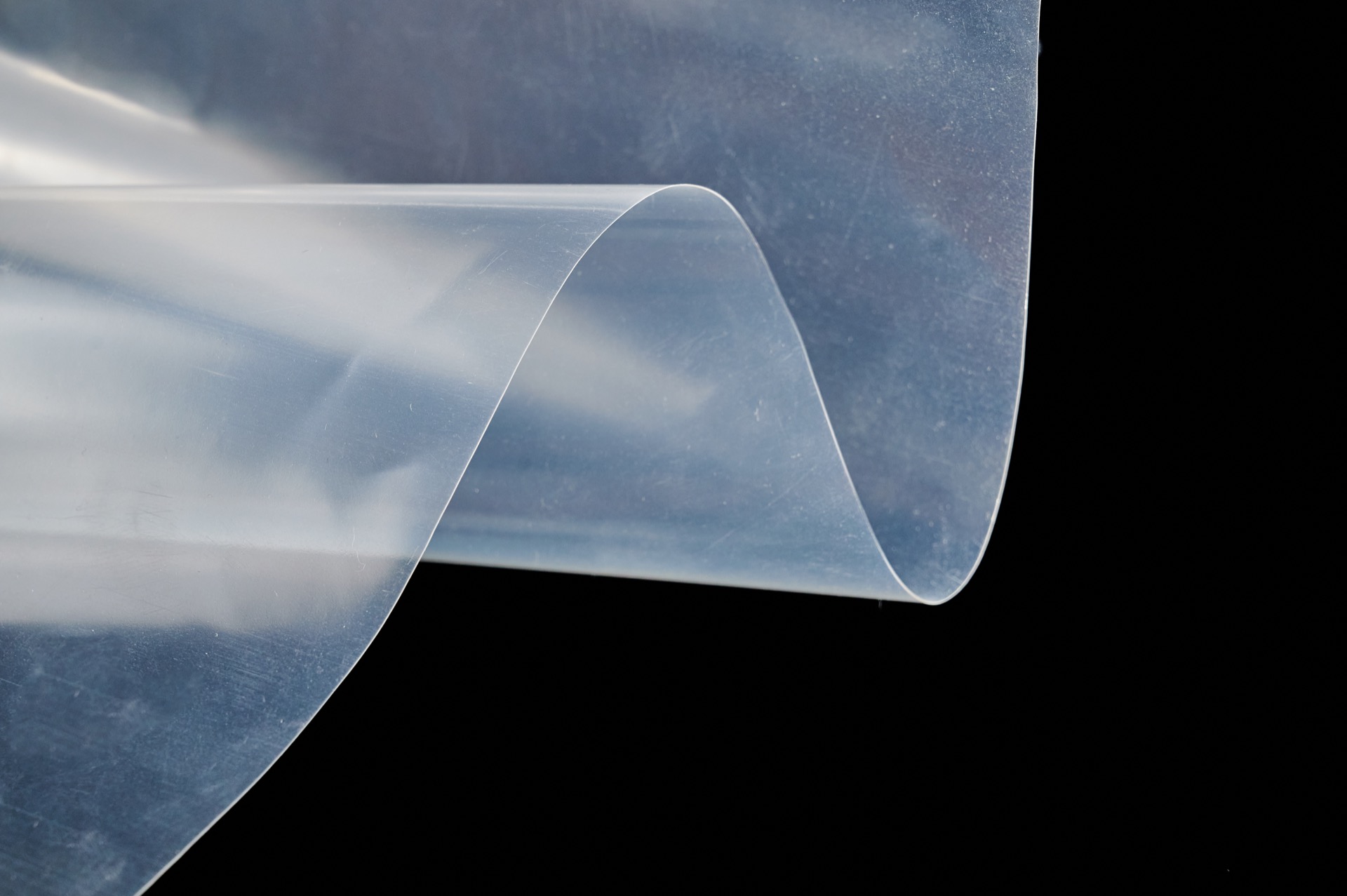

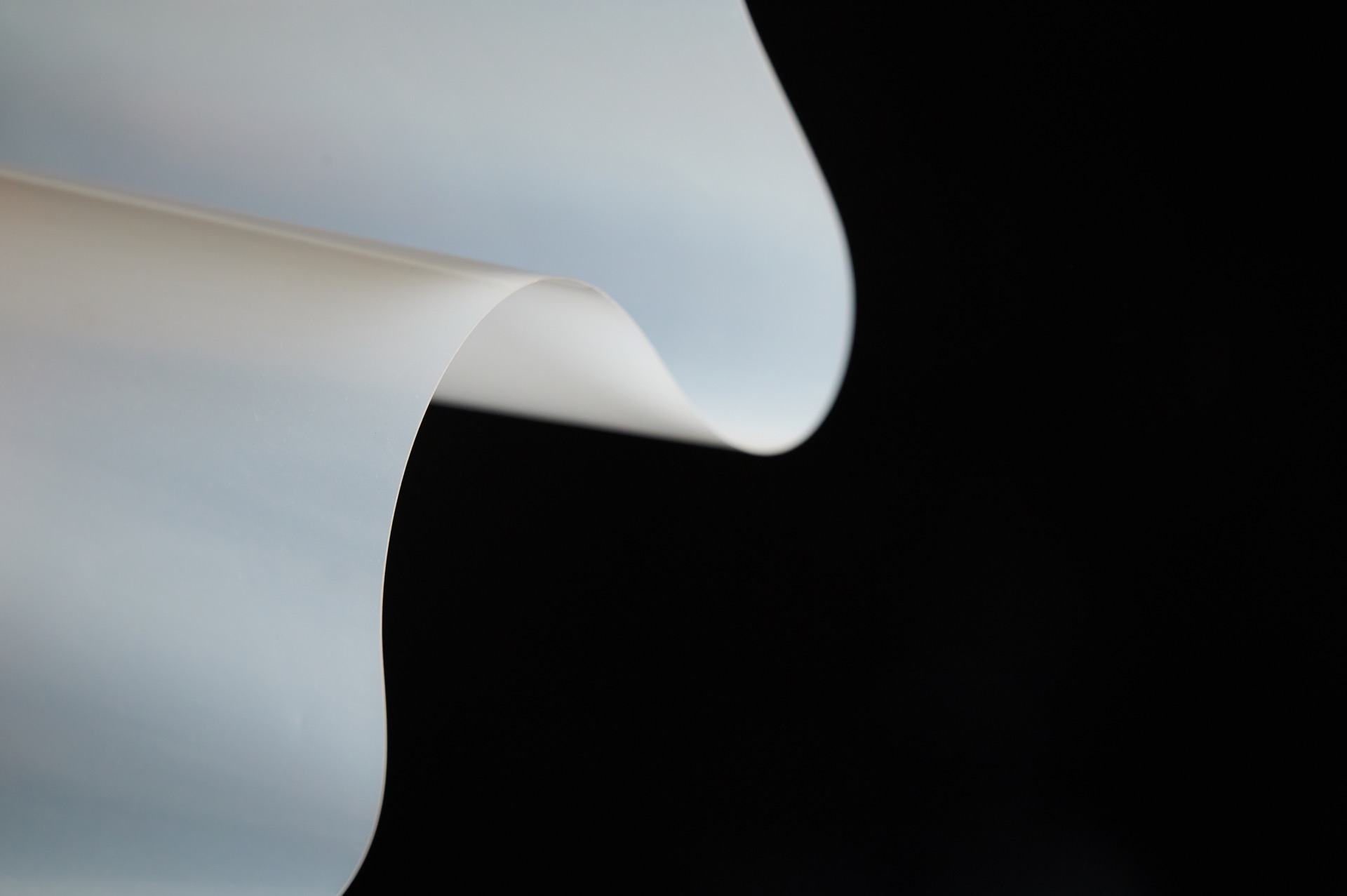

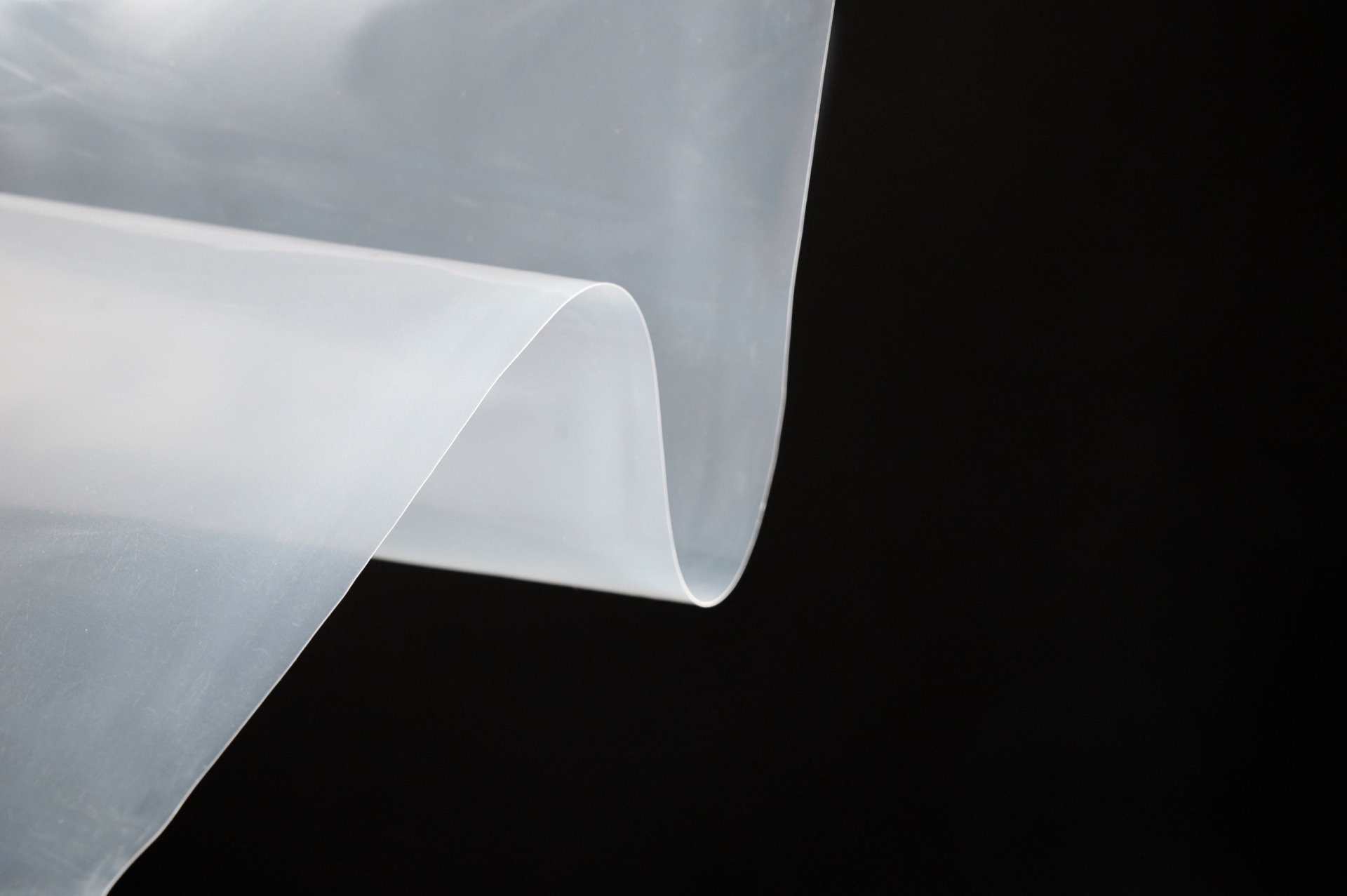

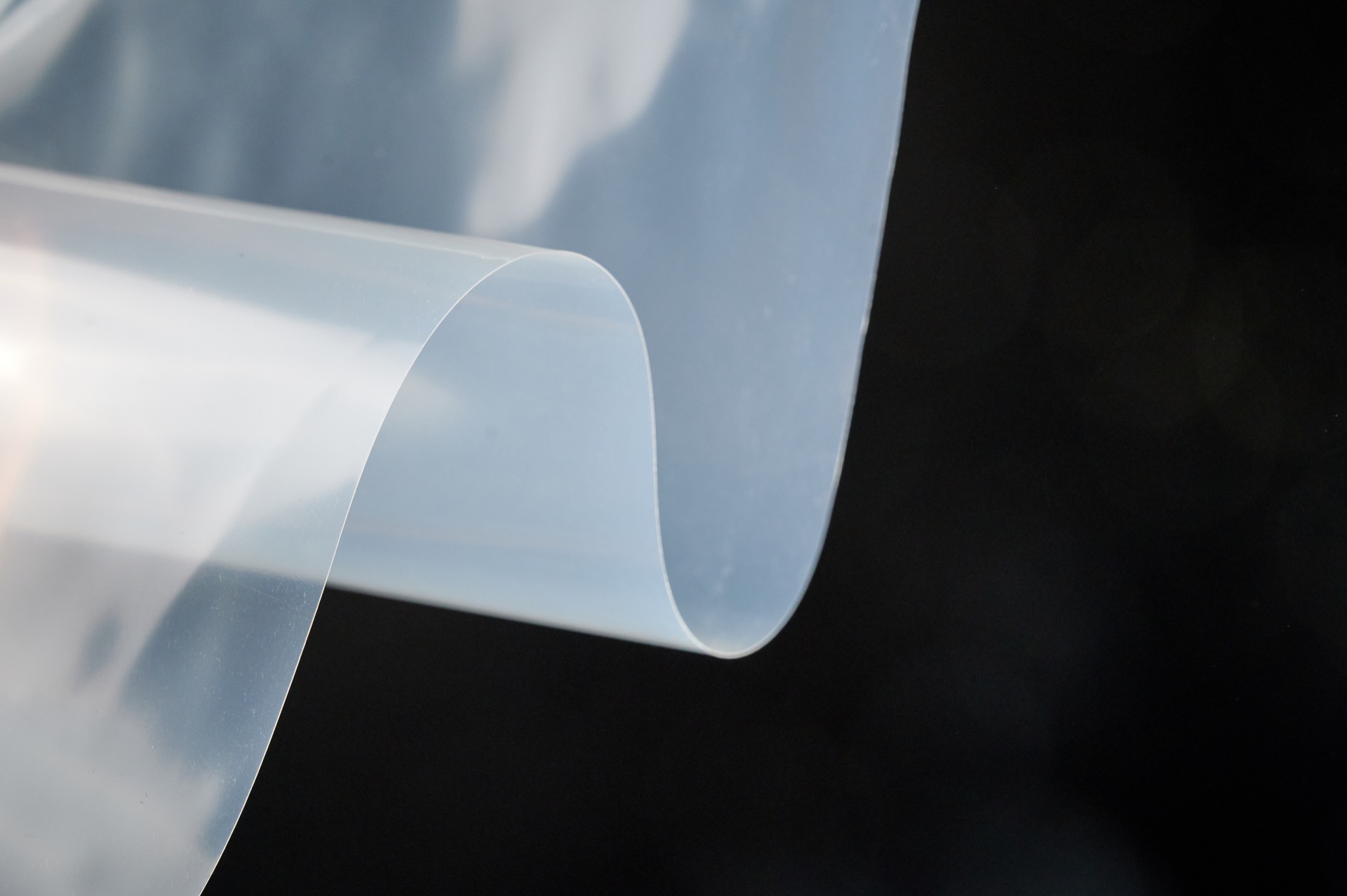

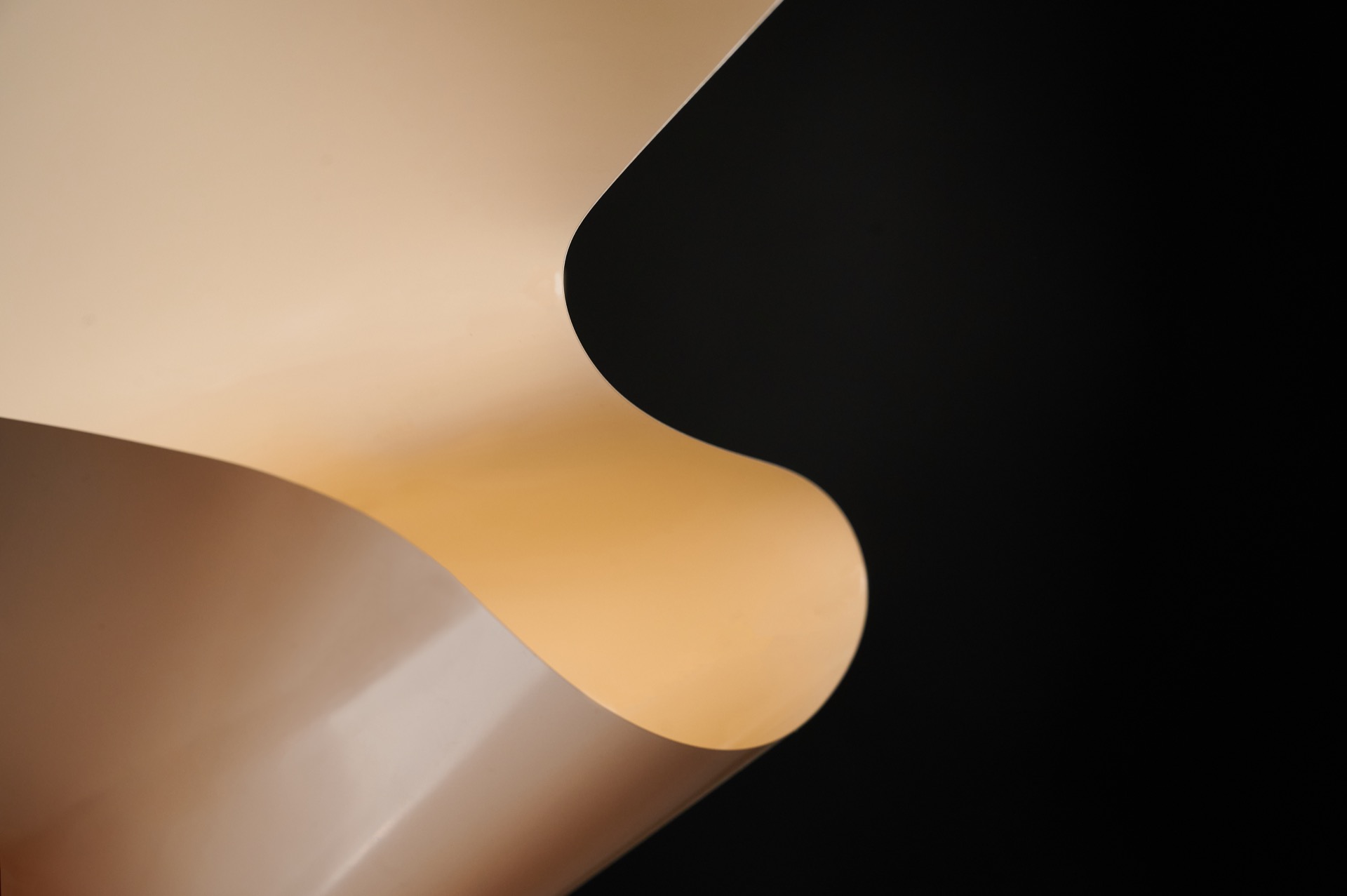

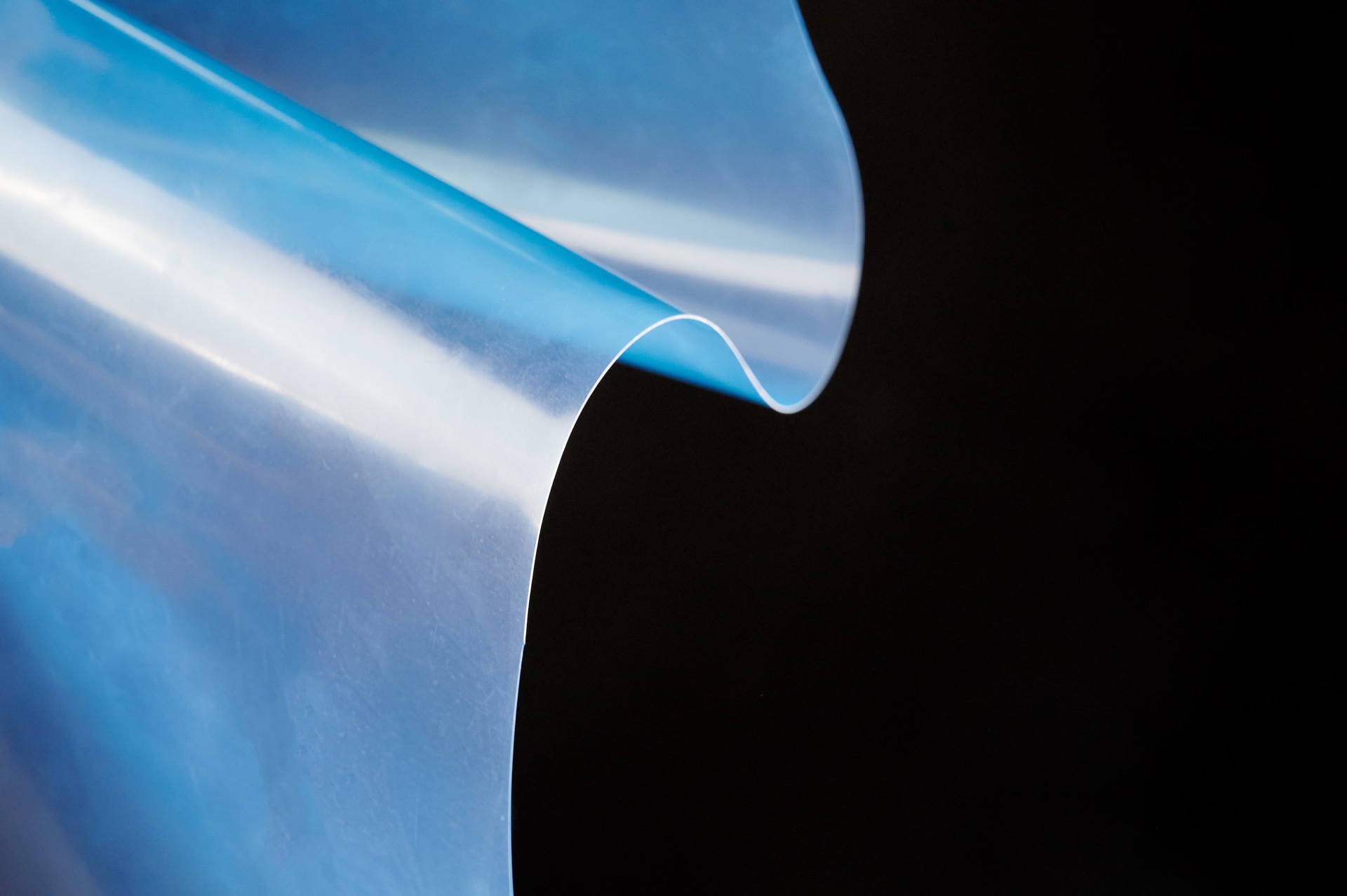

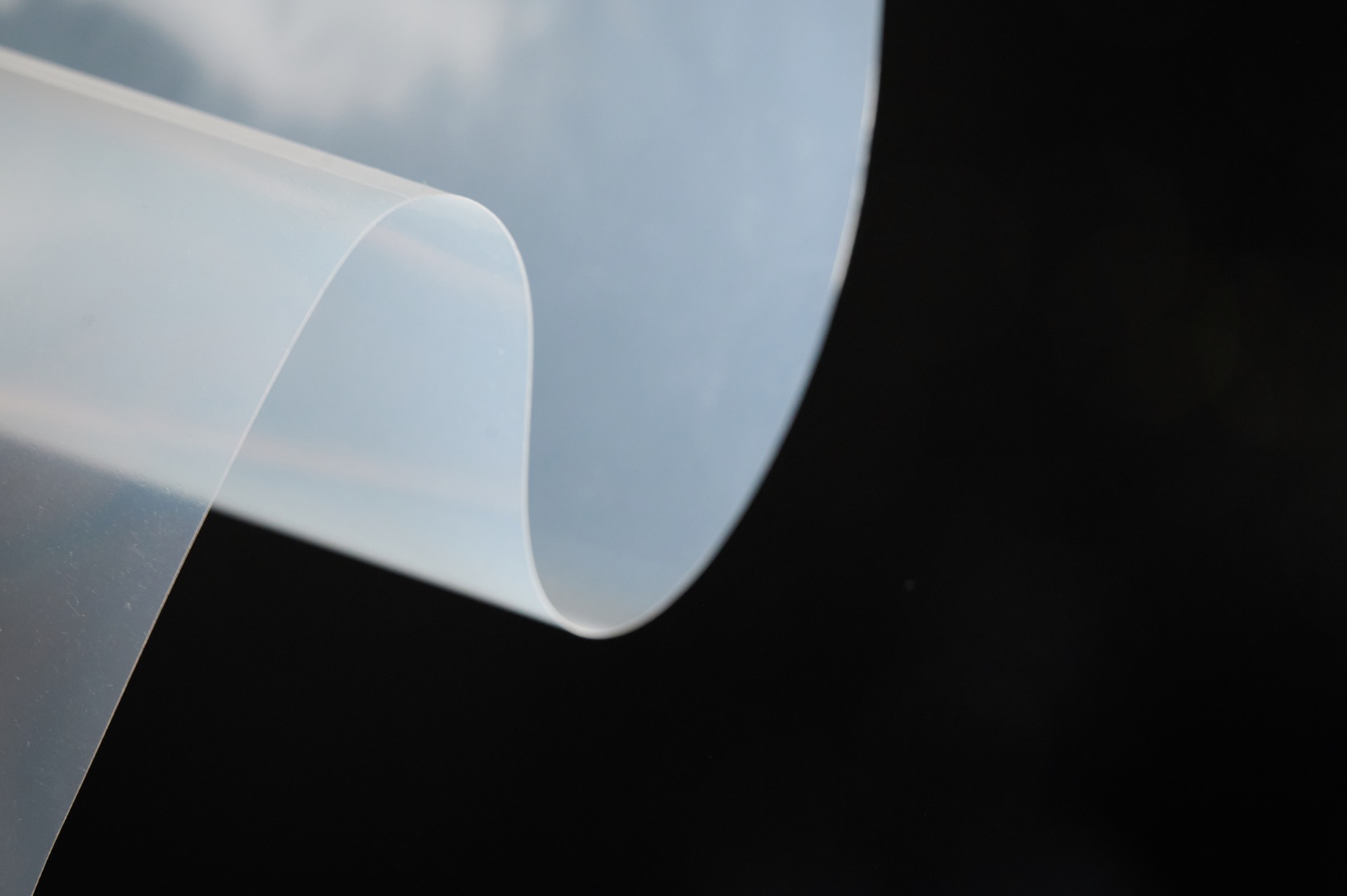

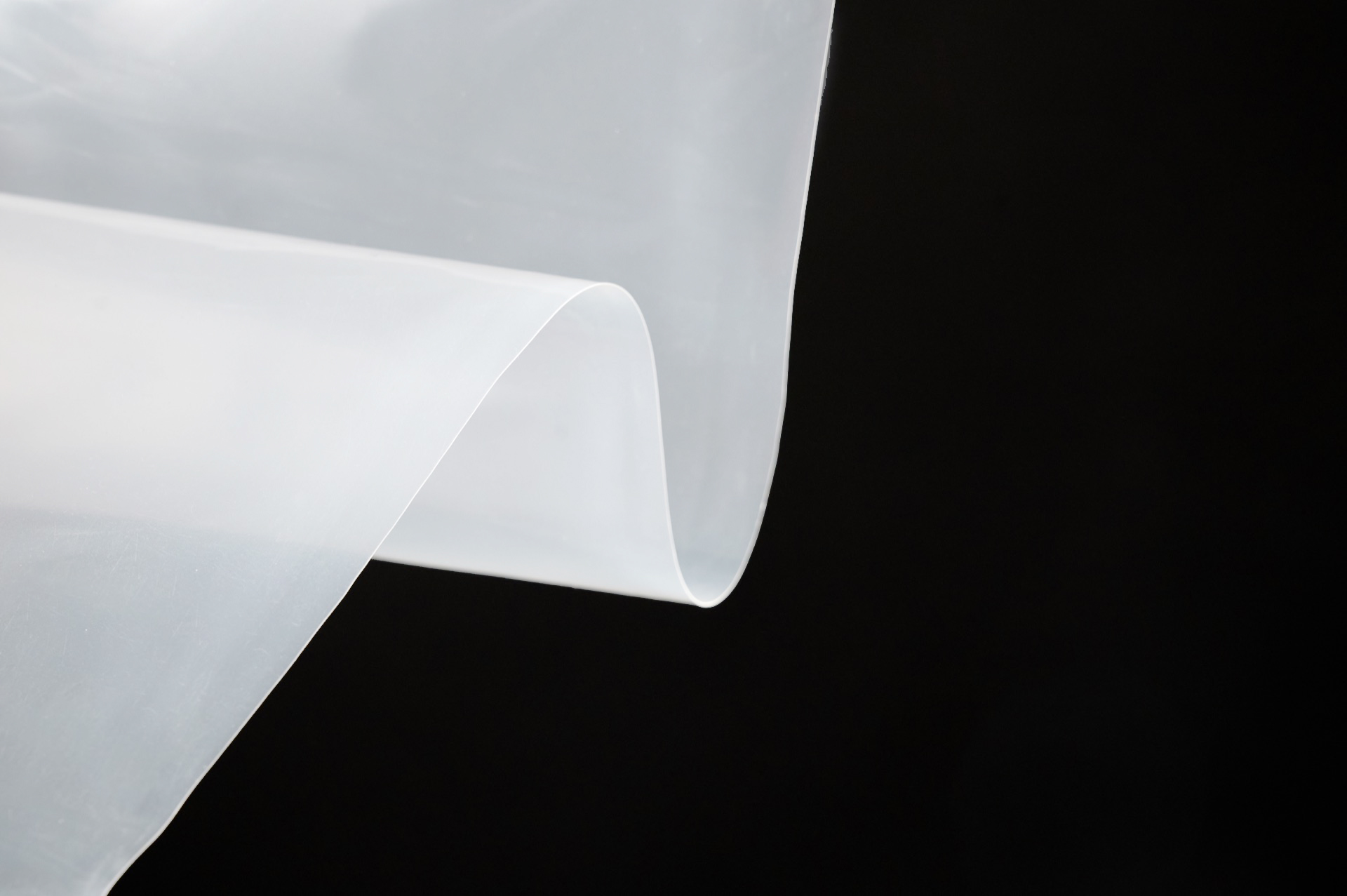

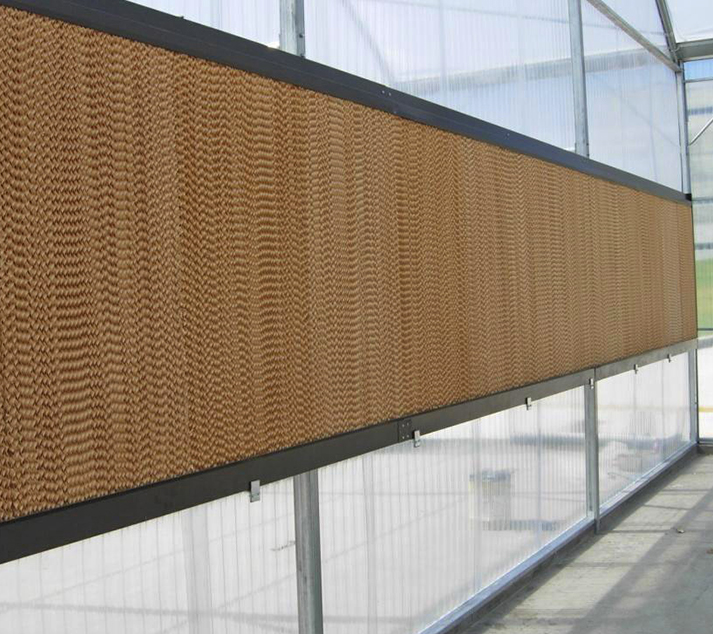

Idromeccanica Lucchini intervention has included the construction of 8 greenhouses of 10 x 130 meters separated from each other and protected by the proven double film coating that has already demonstrated in several other environments its functionality. The diffused light films double layer + 200 in fact create an air cushion insulation that retains the heat in winter and does not increase too much the temperature in summer, thus preventing the damage caused by the climate of Kyrgyzstan, in which there is indeed a significant thermal gap between summer and winter. In order to protect the greenhouses from the insects, monotex nets have also been laid both at the top and at the sides of the greenhouses. The product Lucchini selected for this intervention was the greenhouse Atlantic Evoluzione, which is confirming as a flagship product of the Range

Innovation and Technology

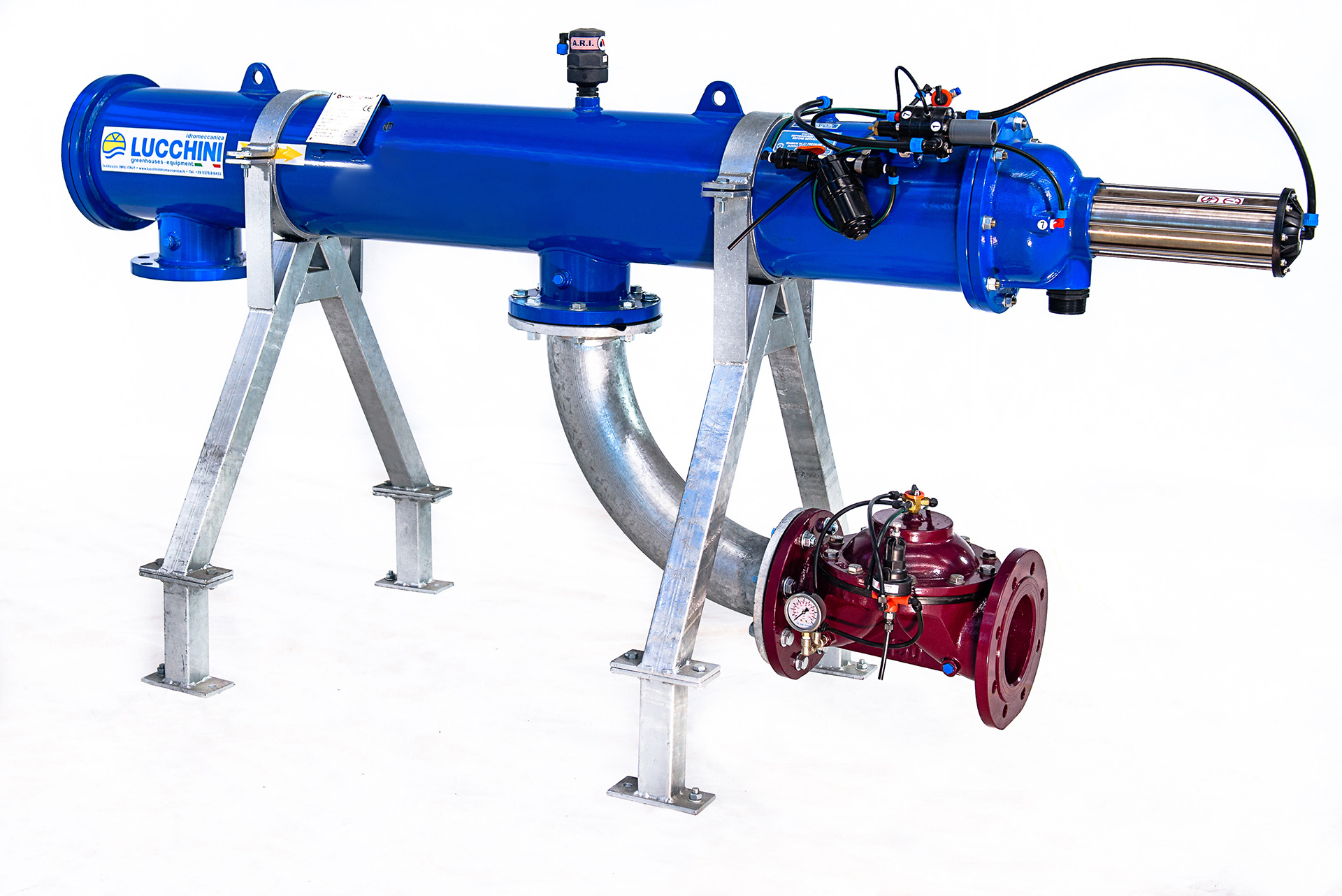

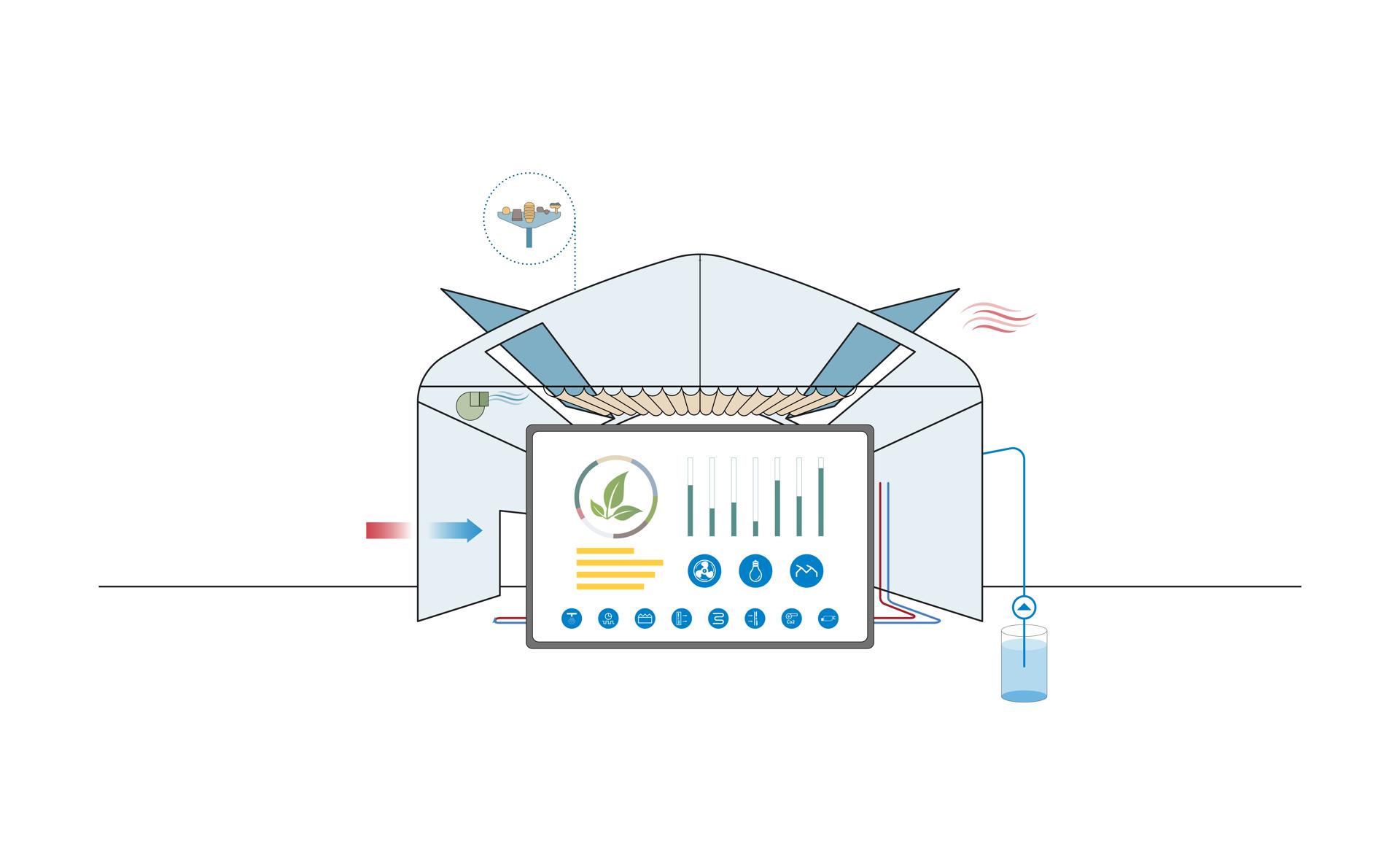

Each greenhouse is a small concentrate of technology as it is completely remote-controlled. Through a computer it is possible to program the openings of the greenhouse to allow the aeration, as well as the heating, irrigation and the distribution of nutrient solution. The fertigation process takes place through the use of irrigation rods for each individual greenhouse and the amount of water and nutrients is carefully calculated to ensure maximum plant health. Heating and fertigation systems are both high Italian technology. The seedlings, sown in special boxes, are then placed in the germination chamber. When the plant is germinated, it is brought into the greenhouse where it remains for some months and finally transplanted in the field when its growing conditions allow the maximum yield in the maximum safety. It was also designed and built a line of washing and disinfection of boxes that, from the field, fall into greenhouse perfectly clean and uncontaminated. The tomato plants grown in greenhouses, not only make more, but tend to produce for more time, also prolonging the harvest period. Each greenhouse is also equipped with rails on which the trolleys that collect the boxes of the plants already grown.

A fully cared Project

The entire plant was designed and built by Idromeccanica Lucchini, which also handled the logistics of transport and assembly of materials. The construction of the greenhouses took place in record time between August and December 2020 thus allowing, as early as 2021, to obtain the first harvest with the seedlings produced in the greenhouses of Idromeccanica Lucchini.

Consulting and After-Sale

Consulting service of Idromeccanica Lucchini goes far beyond the study and design of the best greenhouse system for the cultivation of tomatoes. Lucchini agronomists and technicians, in fact, have followed every stage of the work from the start-up to the training of greenhouse personnel. In addition to this, there is an after-sales consulting service through which the customer can stay in contact with Lucchini specialists, who can meet any technical and agronomic need. Given the success of the first harvests, the project in Kyrgyzstan will soon be expanded at the request of the customer.